Safe Design of Structures

Designer Duties

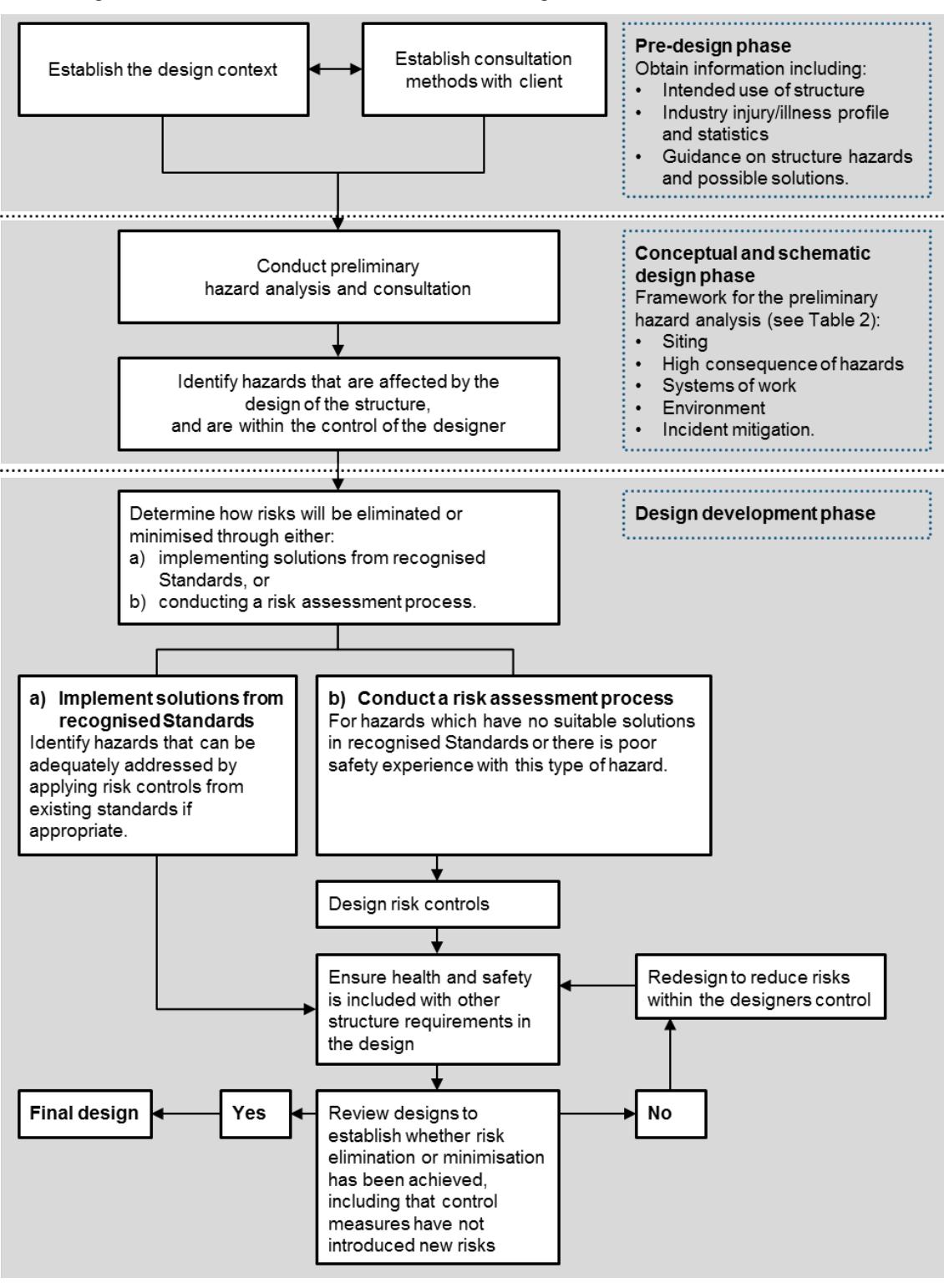

Designers have specific WHS duties under WHS Act s.22 to ensure structures are designed to eliminate or minimize WHS risks.

"Designer" includes:

- Architects

- Engineers (structural, civil, mechanical, electrical)

- Building designers

- Draftspersons

See Designer Duties for comprehensive coverage.

What is Safe Design?

Safe design integrates WHS considerations into design process to eliminate or minimize risks throughout structure's lifecycle:

- Construction

- Use/occupation

- Maintenance

- Demolition

Design for Construction Safety

Falls Prevention

Design features:

- Permanent edge protection (parapets, balustrades)

- Fixing points for temporary edge protection

- Safe roof access (permanent ladders, platforms)

- Avoid or minimize work at heights during construction

Example: Design roof with central walkway and anchor points for harnesses, eliminating need for workers to access fragile areas.

Prefabrication

Eliminate height risks:

- Prefabricate wall panels, trusses at ground level

- Crane into position

- Reduces time working at heights

Example: Prefabricated bathroom pods reduce on-site plumbing/tiling work in confined, elevated spaces.

Construction Sequence

Design to allow safe sequence:

- Consider how structure will be built (not just final form)

- Enable safe temporary works

- Provide support points for formwork

Example: Design floor slabs with edge details that allow guardrails to be installed before slab poured.

Material Selection

Consider:

- Weight (lighter materials easier to handle manually or with smaller plant)

- Size (manageable units reduce manual handling risks)

- Toxicity (specify non-hazardous materials where possible)

Example: Specify lightweight concrete blocks instead of dense concrete blocks (easier manual handling).

Design for Use and Maintenance

Access for Maintenance

Provide safe access to:

- Roofs (gutters, equipment)

- Building services (HVAC, electrical, plumbing)

- Façade (cleaning, repairs)

- Confined spaces (tanks, plant rooms)

Design features:

- Permanent access ladders/stairs

- Platforms and walkways

- Anchor points for fall arrest

- Adequate headroom and workspace

Example: Roof design includes permanent platform around air conditioning units, with guardrails and access ladder.

Eliminate Cleaning Risks

Design to minimize:

- Window cleaning at heights (specify self-cleaning glass or mechanical cleaning systems)

- Gutter cleaning risks (leaf guards, adequate roof drainage)

Example: Commercial building designed with Building Maintenance Unit (BMU) - permanent system for safe façade access.

Services Access

Avoid confined spaces:

- Design accessible plant rooms (not cramped ceiling spaces)

- Provide adequate access openings (not squeeze-through hatches)

- Natural ventilation where possible

Example: Place electrical switchboards in dedicated, accessible room rather than ceiling space.

Design for Demolition

Consider end-of-life:

- Modular construction (easier to dismantle)

- Document hazardous materials used (future reference)

- Removable connections (less cutting/breaking required)

Example: Steel-framed building with bolted connections can be disassembled with less dust/noise/vibration than concrete demolition.

Information to Provide

Designer's Safety Report

Designers should prepare report covering:

1. Purpose and Limits of Design

- Intended use

- Load limits

- Design life

2. Hazards and Risks

- Hazards unique to the particular design that create a risk to persons carrying out construction work

- Residual risks requiring controls

3. Safe Work Recommendations

- Suggested construction methods

- Required temporary works

- Recommended equipment

- Maintenance procedures

4. Hazardous Materials

- Materials used in design (asbestos, lead paint, treated timber)

- Location and quantity

- Safe handling/removal requirements

When to Provide

- With design documentation

- Before construction/installation begins

- Update if design changes

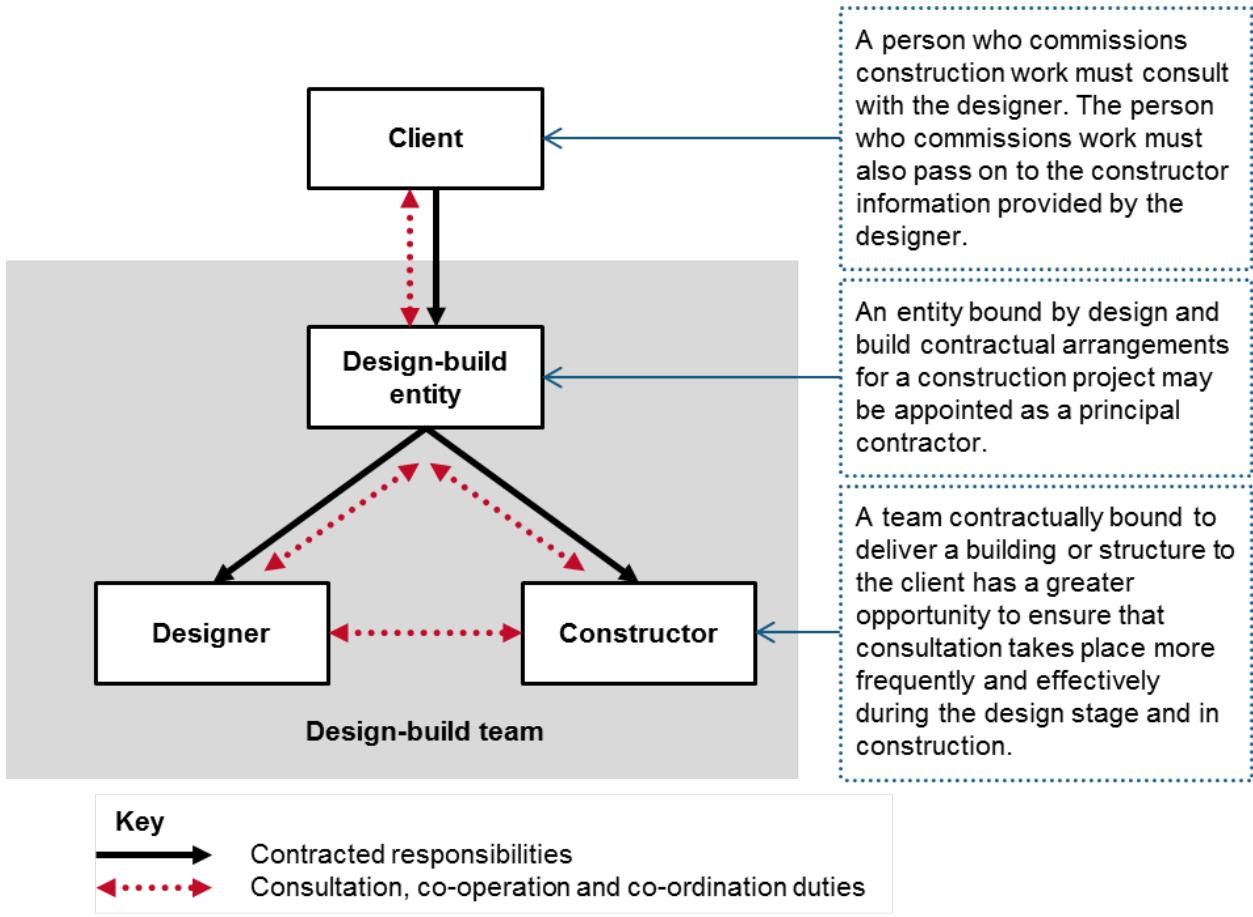

Who Receives

- The Client (PCBU who commissioned the design)

- (Client must then provide it to the Principal Contractor)

- Future occupants/owners

Consultation

Designers must consult with:

- Others involved in design (multi-disciplinary teams)

- PCBUs who will construct structure

- Future users (where known)

Purpose:

- Share WHS knowledge

- Identify hazards early

- Develop practical solutions

Example: Architect consults with scaffolder during design to ensure building façade allows safe scaffold installation.

Practical Examples

Example 1: Residential Roof Design

Hazard: Falls during construction and maintenance.

Design Solutions:

For Construction:

- Trusses prefabricated on ground

- Crane lift into position

- Temporary edge protection fixing points on slab edge

- Roof battens designed to support safety mesh installation

For Maintenance:

- Install permanent gutter guard (eliminates gutter cleaning)

- Roof anchor points at ridge for harness attachment

- Safe access via permanent roof ladder (fixed to wall)

Information Provided:

- Truss drawings showing lift points

- Specification for edge protection fixings

- Anchor point load ratings and installation instructions

Example 2: Commercial Building HVAC Access

Hazard: Falls and confined space risks accessing rooftop equipment.

Design Solutions:

Access:

- Internal staircase to roof (not external ladder)

- Landing at roof access door

- Permanent walkways between equipment (1.2m wide, guardrails)

Work Area:

- Platforms around all equipment (adequate workspace)

- Guardrails on all platforms and roof edges

- Adequate lighting

Confined Space Elimination:

- All plant in open, accessible locations (not cramped ceiling spaces)

- Ventilation openings for natural air flow

Information Provided:

- Roof layout showing walkways and platforms

- Anchor point locations for equipment lifting

- Maintenance access procedures

Example 3: Warehouse Design

Hazards: Falls, manual handling, forklift risks.

Design Solutions:

Structure:

- Adequate floor strength for racking loads

- Wide aisles (3m minimum for forklift operation)

- Level floor (reduces manual handling strain, safer for forklifts)

Loading Docks:

- Recessed loading dock (level with truck bed, eliminates step)

- Dock levelers for height adjustment

- Guardrails at edges

- Wheel stops

Racking:

- Specify racking design loads clearly

- Adequate aisle widths for safe forklift use

- Loading height within ergonomic reach zones

Lighting:

- Adequate lighting for forklift operation (150 lux minimum)

- Emergency lighting for safe evacuation

Information Provided:

- Floor load capacity documentation

- Racking installation requirements

- Safe forklift operating procedures

Benefits of Safe Design

For All Stakeholders:

Fewer Injuries:

- Eliminates hazards at source (most effective control)

- Protects workers throughout structure lifecycle

Lower Costs:

- Reduces incidents (workers compensation, project delays)

- Minimizes expensive retrofits to address WHS issues

- Lower maintenance costs (safer access = faster, cheaper maintenance)

Legal Compliance:

- Meets designer duties under WHS Act

- Reduces liability risks

Better Quality:

- Integrated approach produces better outcomes

- Considers whole lifecycle, not just initial construction

Common Design Hazards to Address

Falls:

- Work at heights during construction

- Roof access for maintenance

- Window cleaning

Manual Handling:

- Heavy materials

- Awkward lifts during construction

Confined Spaces:

- Services in ceiling voids

- Tanks, vessels

Structural Stability:

- During construction (temporary works)

- Demolition sequence

Hazardous Materials:

- Specify non-hazardous alternatives

- Document unavoidable hazardous materials