Asbestos Management Overview

What is Asbestos?

Asbestos is a naturally occurring fibrous mineral that was extensively used in Australian construction until the late 1980s. When asbestos-containing materials (ACM) are disturbed, microscopic asbestos fibres can be released into the air and, if inhaled, cause serious lung diseases including:

- Asbestosis: Scarring of lung tissue

- Mesothelioma: Aggressive cancer of lung/chest lining

- Lung cancer: Increased risk, especially for smokers

- Pleural disease: Lung lining disorders

There is no known safe level of asbestos exposure. All exposure should be eliminated or minimized so far as reasonably practicable.

Prohibitions on Asbestos

WHS Regulation 419 prohibits:

- Mining or manufacturing asbestos

- Supplying, transporting, or using asbestos

- Installing or fixing asbestos

- Disturbing or removing asbestos (except by licensed removalist)

Exceptions:

- Asbestos removal by licensed asbestos removalist

- Asbestos-related work (minor work not requiring removal)

- Transport for disposal by licensed removalist

- Natural occurrence management

Who Has Duties?

Person Conducting a Business or Undertaking (PCBU)

Must:

- Identify if asbestos is present at workplace

- Maintain asbestos register

- Prepare asbestos management plan

- Manage asbestos-related risks

- Ensure only licensed removalists remove asbestos

- Provide information and training

- Arrange health monitoring where required

Person with Management or Control of Workplace

Includes building owners, facility managers, and property managers. Must:

- Determine if asbestos is present

- Prepare and maintain asbestos register

- Prepare and maintain asbestos management plan

- Make register and plan accessible

Workers

Must:

- Follow safe work procedures for asbestos

- Use PPE as instructed

- Report damaged or deteriorating ACM

- Attend health monitoring if required

Identifying Asbestos at the Workplace

Where Asbestos May Be Found

Pre-2004 Construction: Any building, structure, plant, or equipment constructed or installed before 31 December 2003 should be assumed to contain asbestos unless proven otherwise.

Common ACM in Construction:

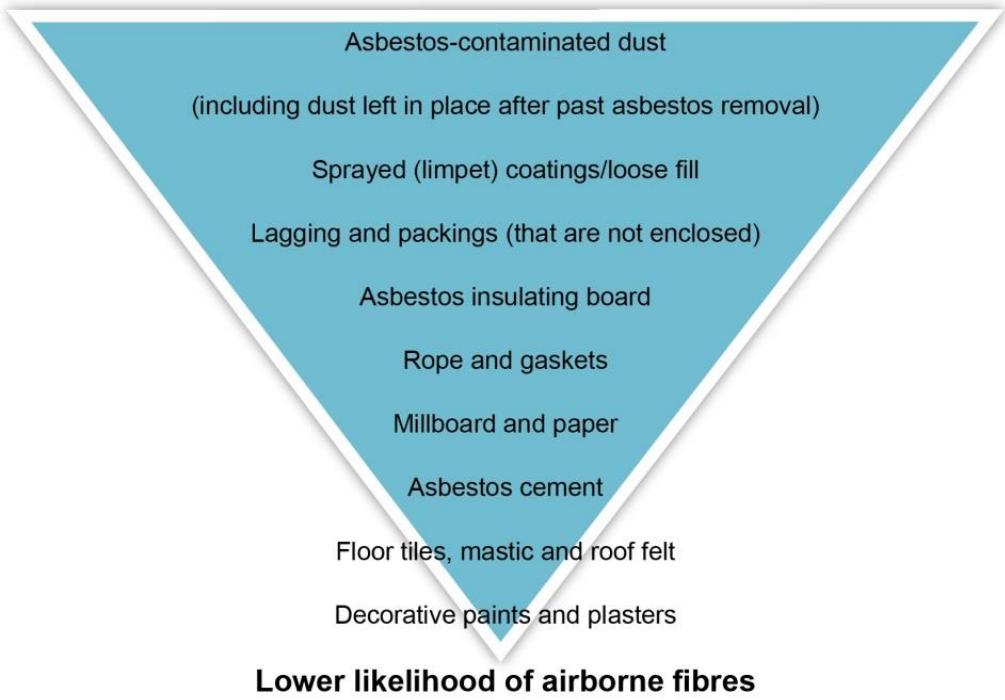

Friable Asbestos (crumbles easily when dry):

- Pipe and boiler lagging

- Sprayed asbestos insulation/fireproofing

- Asbestos rope and gaskets

- Some ceiling tiles and panels

Non-Friable Asbestos (bonded, more stable):

- Asbestos-cement (fibro) sheeting (walls, roofs, eaves)

- Asbestos-cement pipes and guttering

- Vinyl floor tiles with asbestos backing

- Roofing felt and shingles

- Electrical switch boards and meter boxes

- Brake pads and clutches (older vehicles/equipment)

For pre-2004 buildings, presume asbestos is present unless a competent person has confirmed its absence through sampling or documented evidence exists.

Identification Methods

Visual Inspection:

- Competent person inspects workplace

- Identifies suspected ACM based on age, appearance, location

- Documents findings

Sampling and Analysis: When uncertainty exists:

- Samples collected by competent person

- Sent to NATA-accredited laboratory

- Analysis using approved methods (polarized light microscopy, X-ray diffraction)

Never sample yourself unless trained and using appropriate controls.

Consulting Records:

- Building plans and specifications

- Previous asbestos surveys

- Manufacturer documentation

Asbestos Register

What is Required (WHS Reg 422)

Must contain:

- Location of asbestos or ACM (site plans, photos)

- Type of asbestos (chrysotile, amosite, crocidolite) if known

- Form of asbestos (friable or non-friable)

- Condition of asbestos

- Date of identification

Maintaining the Register

- Update when asbestos identified or removed

- Review at intervals (at least once every five years)

- Revise if changes to asbestos condition

- Keep readily accessible to workers, HSRs, and anyone likely to disturb asbestos

Construction Site Requirement: Obtain asbestos register from building owner before commencing demolition or refurbishment work.

Asbestos Management Plan

What is Required (WHS Reg 424)

Must include:

- Information from asbestos register

- Decisions, reasons, and control measures for asbestos management

- Procedures for incidents involving asbestos

- Training requirements for workers

- Procedures for reviewing the plan

Control Measures in Plan

For Asbestos in Good Condition:

- Leave in place and monitor condition

- Label and signage to indicate presence

- Prevent unauthorized disturbance

- Regular inspections

For Damaged or Deteriorating Asbestos:

- Restrict access to area

- Arrange licensed removal, or

- Arrange repair/enclosure by competent person

Reviewing the Plan

Review and revise if:

- Control measures not effective

- Before changes that may affect asbestos

- Relevant new information becomes available

- Incident involving asbestos

- HSR requests review

Managing Asbestos Risks

Hierarchy of Control for Asbestos

Level 1: Elimination (Remove Asbestos)

Most effective control. Asbestos removal:

- Must be performed by licensed asbestos removalist

- Class A licence for friable asbestos (any quantity)

- Class B licence for non-friable asbestos >10 m²

- Notification to regulator required (5 days for Class A work)

See Code of Practice: How to safely remove asbestos

Level 2: Enclose or Seal Asbestos

When removal not immediately practicable:

Enclosure:

- Build physical barrier around ACM

- Example: Boxing in asbestos pipes, constructing barriers around ACM wall sheeting

Encapsulation/Sealing:

- Apply sealant over ACM surface to bind fibres

- Example: Painting asbestos-cement with approved sealant

- Regular inspection required to ensure integrity

Level 3: Administrative Controls and PPE

Used during asbestos-related work and removal:

- Safe work method statements

- Competent supervision

- Exposure monitoring

- Decontamination procedures

- Restricted access

- Respiratory protective equipment (P1 or P2 masks minimum)

- Disposable coveralls

- Face shields or safety glasses

Asbestos-Related Work

Definition: Work on, adjacent to, or that disturbs ACM but does not involve removal.

Examples:

- Drilling holes in asbestos-cement sheeting for cable installation

- Cleaning gutters on asbestos-cement roofs

- Sealing or painting asbestos surfaces

- Inspection of asbestos friction materials

Requirements:

- May be performed without asbestos removal licence

- Must follow recommended safe work practices

- Must not result in asbestos removal

- If work causes ACM to come loose or be removed, work must stop and licensed removalist engaged

Safe Work Practices

General Principles:

- Wet methods to suppress dust

- Use hand tools (not power tools where possible)

- Minimize disturbance

- Controlled work area with signage

- Decontamination facilities

- Proper waste disposal

Example: Drilling ACM Sheeting

- Isolate work area, erect signage

- Ensure asbestos register and management plan available

- Wet area around drilling location

- Use sharp drill bit, low speed, gentle pressure

- Wet methods during drilling

- Seal hole immediately after drilling

- Clean up using wet wipes (never dry sweep or compressed air)

- Dispose of waste as asbestos contaminated

Demolition and Refurbishment Work

Before Commencing Work (WHS Reg 443)

Must:

- Obtain or prepare asbestos register for structure

- If no register exists, presume asbestos present or arrange inspection/sampling

- Make register available to all workers

- If asbestos identified, arrange licensed removal before demolition/refurbishment

Demolishing or refurbishing structures that may contain asbestos without proper identification is prohibited and creates extreme risk.

Construction Project Requirements:

- Principal contractor must obtain asbestos information

- Provide to all contractors and subcontractors

- Coordinate asbestos removal before other work

- Ensure removal by licensed removalist

Health Monitoring

When Required (WHS Reg 448)

Health monitoring must be provided if worker:

- Carries out licensed asbestos removal work

- Carries out asbestos-related work on a regular basis

- Is at risk of exposure exceeding exposure standard

What it Involves:

- Medical examination by qualified physician

- Respiratory function tests

- Chest X-ray or CT scan

- Health records maintained for 30 years

Worker Rights:

- Access to own health monitoring results

- Confidential medical information

See Health Monitoring for detailed requirements.

Training Requirements

All Workers at Risk of Exposure:

- Nature of asbestos and health risks

- Where asbestos is located (from register)

- Safe work procedures

- Use of PPE and decontamination

- Emergency procedures

Asbestos Removalists:

- Completion of approved asbestos removal training

- Understanding of licensing requirements

- Air monitoring procedures

- Clearance certificate procedures

Exposure Monitoring

When Required:

- During licensed asbestos removal

- When uncertain if exposure standard exceeded

- To verify control measure effectiveness

Exposure Standard: 0.1 fibres per millilitre of air (measured over 8-hour period)

Who Can Monitor:

- Competent person with appropriate equipment

- Air samples analyzed by NATA-accredited laboratory

Disposal of Asbestos Waste

Requirements:

- Wrap or seal to prevent fibre release

- Label as containing asbestos

- Transport by licensed asbestos removalist or authorized person

- Dispose at licensed landfill accepting asbestos

- Complete waste disposal dockets

Never:

- Place asbestos in general waste bins

- Break up or crush ACM

- Reuse or recycle ACM

Emergency Response

If Asbestos Damaged or Disturbed:

- Stop Work Immediately

- Restrict Access to affected area

- Wet Down disturbed material if safe to do so

- Notify PCBU and health and safety representative

- Seek Expert Advice - contact licensed asbestos assessor

- Arrange Clearance - air monitoring and clearance certificate before re-entry

- Review Controls - update management plan

If Worker Exposed:

- Remove from area immediately

- Decontaminate (wet wipe exposed skin, remove and bag contaminated clothing)

- Arrange medical assessment

- Report incident to regulator if exposure exceeds standard

- Arrange health monitoring

Practical Construction Example

Scenario: Commercial building refurbishment built in 1985

Step 1: Identify Asbestos

- Obtain building owner's asbestos register (if exists)

- If no register, engage licensed asbestos assessor

- Assessor conducts inspection and sampling

- Laboratory analysis confirms asbestos-cement sheeting in ceiling and wall panels

Step 2: Asbestos Register and Plan

- Register updated with exact locations and condition

- Management plan prepared specifying removal required

- All workers provided with register and plan

- Toolbox talk conducted

Step 3: Engage Licensed Removalist

- Licensed Class B asbestos removalist engaged

- Removalist prepares removal control plan

- Notification lodged with regulator (5 days before work)

- Exclusion zone established

Step 4: Removal Work

- Asbestos sheeting removed following licensed procedures

- Air monitoring conducted during removal

- Clearance certificate issued by independent assessor

- Waste transported to licensed landfill

Step 5: Refurbishment Proceeds

- Clearance certificate confirms area safe

- Register updated to show asbestos removed

- Refurbishment work commences

Related Topics

Code of Practice References

Safe Work Australia provides comprehensive guidance on managing and removing asbestos.