Confined Spaces

What is a Confined Space?

A confined space is an enclosed or partially enclosed space that:

- Is not designed or intended for continuous human occupancy, AND

- Has one or more of these characteristics:

- Limited entry/exit

- Unfavorable natural ventilation

- Risk of harmful atmosphere

- Risk of engulfment

Common Construction Confined Spaces:

- Trenches/excavations (only if specific hazardous criteria met, not based on depth alone)

- Tanks, vessels, silos

- Pits, sumps, wells

- Sewers, drains, culverts

- Roof spaces with limited access

- Tunnels and shafts

- Bins and hoppers

Confined spaces kill workers quickly. Most deaths occur during attempted rescues by untrained persons.

Major Hazards

Atmospheric Hazards

Oxygen Deficiency:

- Normal oxygen: 20.9%

- Safe working level: 19.5-23.5%

- < 19.5%: Drowsiness, unconsciousness, death

- Causes: Consumption by chemical processes, displacement by other gases

Toxic Gases:

- Carbon monoxide (CO) - colorless, odorless, deadly

- Hydrogen sulfide (H₂S) - "rotten egg" smell, toxic

- Sewer gases, chemical vapors

Flammable Atmospheres:

- Methane, LPG, solvents

- Risk of fire/explosion

Toxic Dusts/Fumes:

- Welding fumes in enclosed spaces

- Dust accumulation

Physical Hazards

- Burial by grain, sand, liquids

- Can occur rapidly

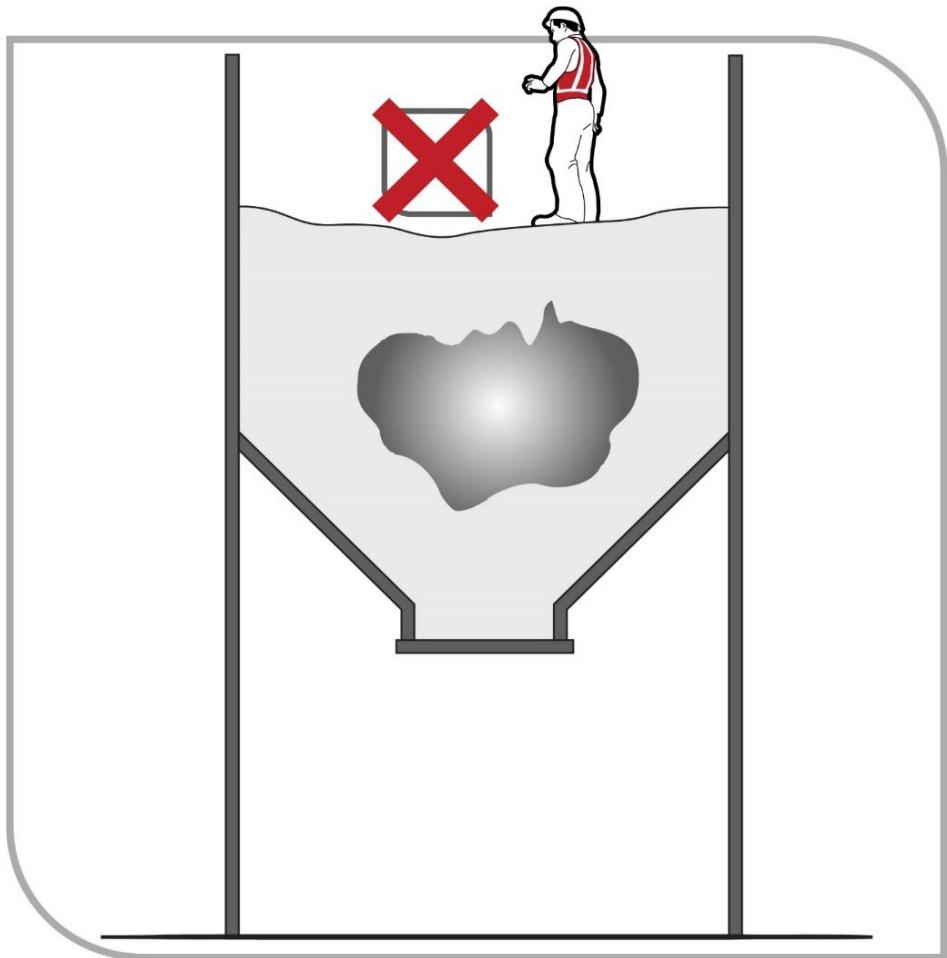

Figure: Example of 'bridging' which may result in engulfment

Figure: Example of 'bridging' which may result in engulfment

Entrapment:

- Limited escape routes

- Difficult rescue access

Temperature Extremes:

- Heat stress in hot confined spaces

- Hypothermia in cold/wet spaces

Other:

- Noise, slips/trips, falling objects

- Mechanical equipment

Identifying Confined Spaces

Risk Assessment Required: Assess each space before entry to determine if it's a confined space.

Consider:

- Is it enclosed/partially enclosed?

- How many entry/exit points?

- How quickly could atmosphere become hazardous?

- What work will be done inside (might create hazards)?

- Has space contained hazardous substances?

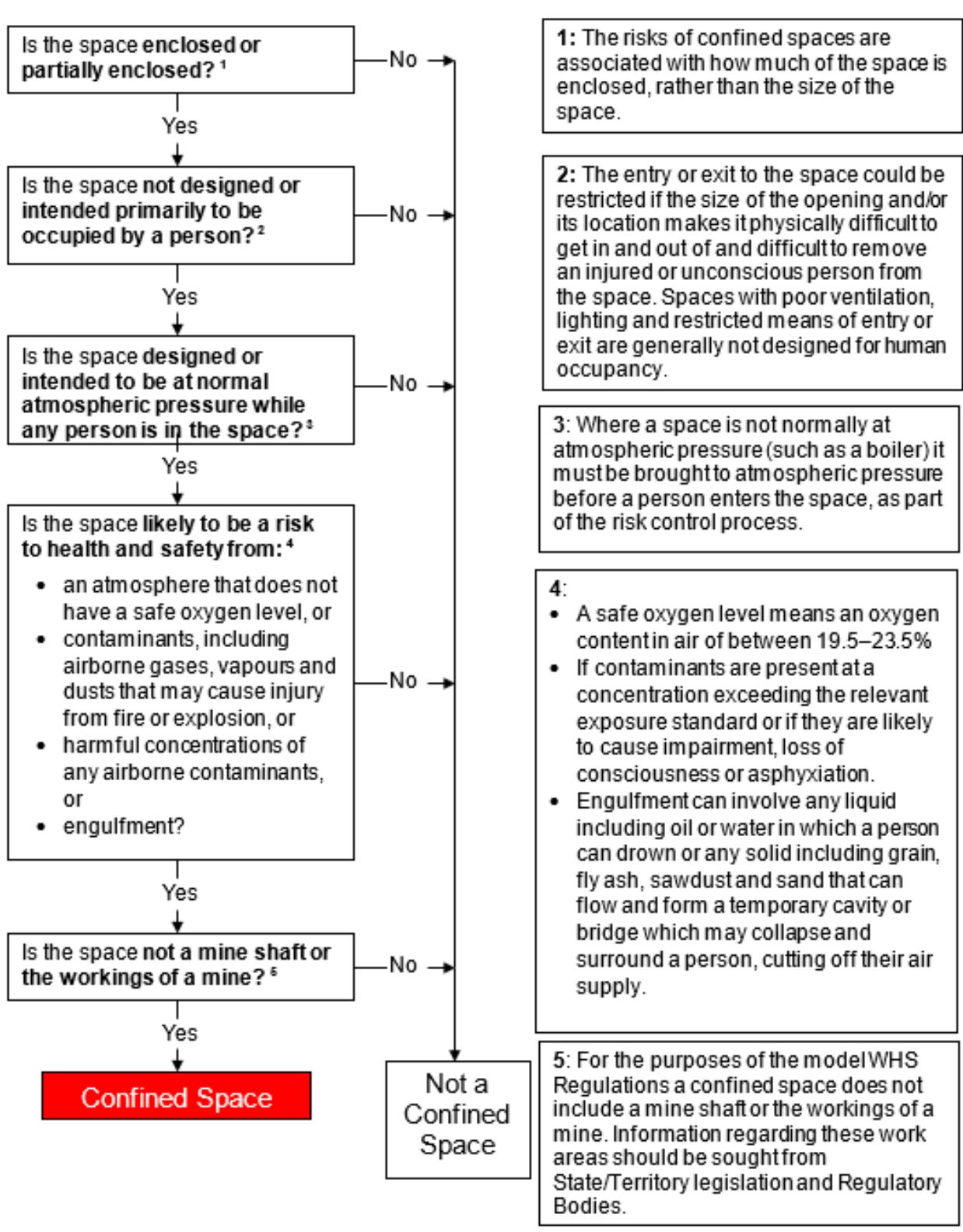

Figure: Flowchart for identifying a confined space

Figure: Flowchart for identifying a confined space

When is Confined Space Entry HRCW?

Work in/near confined space is HRCW requiring SWMS.

Managing Confined Space Risks

Hierarchy of Control

Level 1: Elimination

Eliminate need to enter:

- Remote inspection (cameras, drones)

- Automation/robotics

- Design changes

Example: Install tank with external manholes for cleaning instead of requiring internal entry.

Level 2: Minimize Risks if Entry Required

Engineering Controls:

Ventilation:

- Forced ventilation to maintain safe atmosphere

- Fresh air supply

- Continuous operation during entry

Isolation:

- Isolate from energy sources (electrical, mechanical, hydraulic)

- Lockout/tagout

- Blank off pipes (prevent ingress of substances)

- Drainage to prevent flooding

Figure: Example of tag and lockout isolation

Figure: Example of tag and lockout isolation

Atmospheric Monitoring:

- Continuous monitoring during entry

- Test for oxygen, flammable gases, toxic gases

- Calibrated instruments

- Alarms if atmosphere unsafe

Access/Egress:

- Improve access points where possible

- Ensure rescue equipment can be used

Level 3: Administrative/PPE

Entry Permits:

- Written authority to enter

- Confirms controls in place

- Authorizer signs permit

Training:

- Confined space awareness

- Emergency procedures

- Equipment use

Standby Person:

- Remains outside

- continuously monitor the wellbeing of those inside the space

- observe the work being carried out where practicable

- Maintains communication

- Raises alarm if needed

- Does not enter for rescue

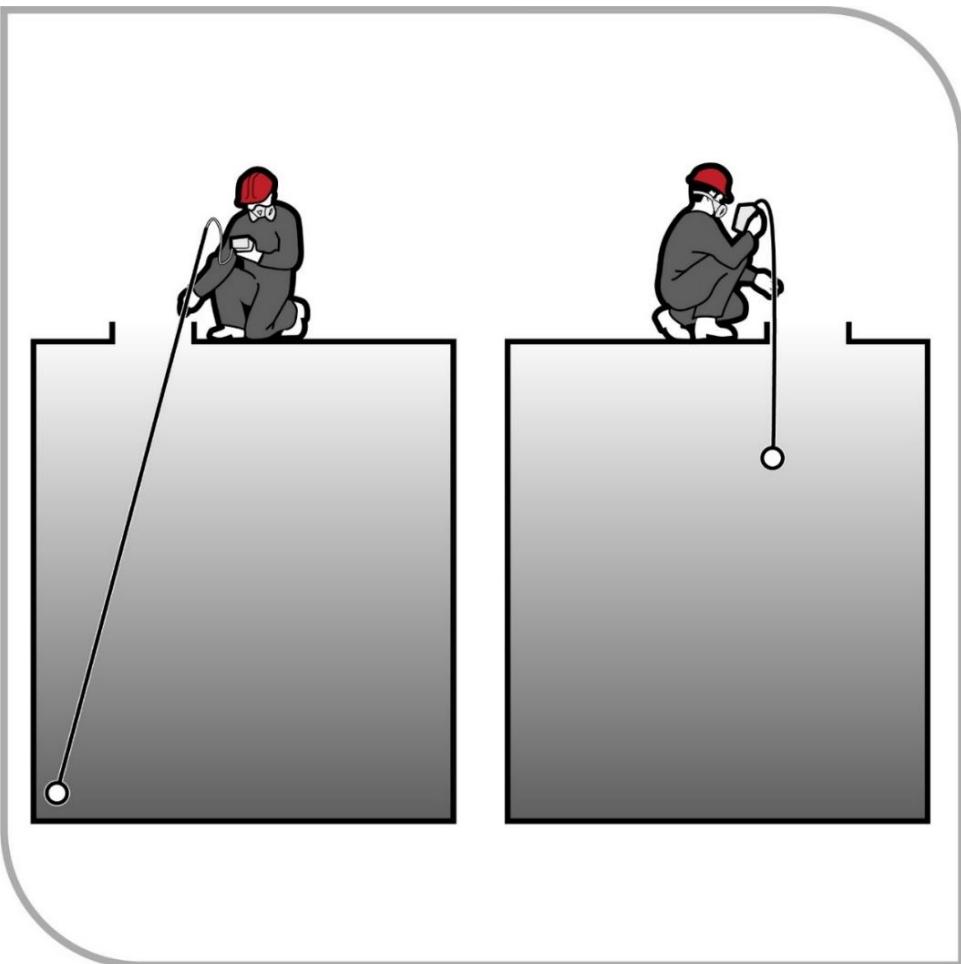

Figure: Standby person monitoring confined space with rescue equipment

Figure: Standby person monitoring confined space with rescue equipment

Respiratory Protection:

- Supplied-air respirators (continuous fresh air)

- Self-contained breathing apparatus (SCBA) for IDLH atmospheres

- NOT air-purifying respirators in oxygen-deficient spaces

Other PPE:

- Full-body harness with retrieval line

- Hard hat, gloves, boots

- Protective clothing

Atmospheric Testing

Before Entry:

- Test atmosphere from outside

- Test top, middle, bottom (gases stratify)

- Only enter if safe

During Entry:

- Continuous monitoring

- Alarm if atmosphere changes

- Exit immediately if unsafe

Figure: Atmospheric testing of different levels (gases stratify)

Figure: Atmospheric testing of different levels (gases stratify)

Testing For:

- Oxygen: 19.5-23.5% safe

- Flammable gases: <5% of lower explosive limit (LEL)

- Toxic gases: Below exposure standards (CO, H₂S, etc.)

Equipment:

- Multi-gas detector (O₂, LEL, CO, H₂S minimum)

- Calibrated and bump-tested

- Alarms set correctly

Entry Permits

Permit Must Specify:

- Location and description of space

- Purpose of entry

- Duration of entry

- Names of entrants, standby person, supervisor

- Hazards identified

- Control measures required

- Atmospheric test results

- Emergency contact numbers

- Authorizer signature

Before Entry:

- All control measures verified in place

- All personnel briefed

- Permit signed

During Entry:

- Permit displayed at entry point

- Valid for specified duration only

- Cancelled if conditions change

Emergency Response and Rescue

Untrained, unequipped rescue attempts kill more people than the original incident. DO NOT ENTER.

Requirements:

Rescue Plan:

- Specific to confined space

- Method to retrieve without entry (preferred)

- Rescue equipment identified

- Trained rescue personnel or emergency services

- Regular drills

Retrieval Equipment:

- Full-body harness on entrant

- Retrieval line attached

- Mechanical retrieval winch (can lift unconscious person)

- Available for immediate use

Communication:

- Constant communication between entrant and standby person

- Method: visual, verbal, radio, rope signals

- Standby person raises alarm immediately if communication lost

If Emergency:

- Standby person raises alarm

- Calls emergency services (000)

- Attempts non-entry rescue if safe (use retrieval line/winch)

- Does NOT enter confined space

- Provides information to emergency responders

Practical Example

Scenario: Inspecting inside concrete water tank (empty, 3m deep)

Before Entry

Identify: Confirmed confined space (enclosed, limited exit, unfavorable ventilation)

Assess Hazards:

- Oxygen deficiency (enclosed space)

- Slip hazard (wet surfaces)

- Limited access (single manhole 600mm diameter)

Controls Implemented:

Engineering:

- Forced ventilation (blower supplying fresh air)

- Continuous atmospheric monitoring (O₂, LEL, CO)

- Tank isolated (valves locked shut, tagged)

- Lighting installed

Administrative:

- Entry permit prepared and authorized

- Entrant and standby person briefed

- Emergency services notified (on standby)

PPE:

- Full-body harness with retrieval line

- Supplied-air respirator (continuous fresh air supply)

- Hard hat, gloves, non-slip boots

During Entry

- Atmospheric test: O₂ 20.8%, LEL 0%, CO 0 ppm ✓

- Standby person positioned at entry

- Communication maintained (verbal through manhole)

- Continuous monitoring (alarm if atmosphere changes)

- Inspection completed in 20 minutes

- Entrant exits safely

Result

Safe entry and exit. Continuous monitoring and standby person provided safety net.