Managing Risks of Respirable Crystalline Silica

What is Respirable Crystalline Silica?

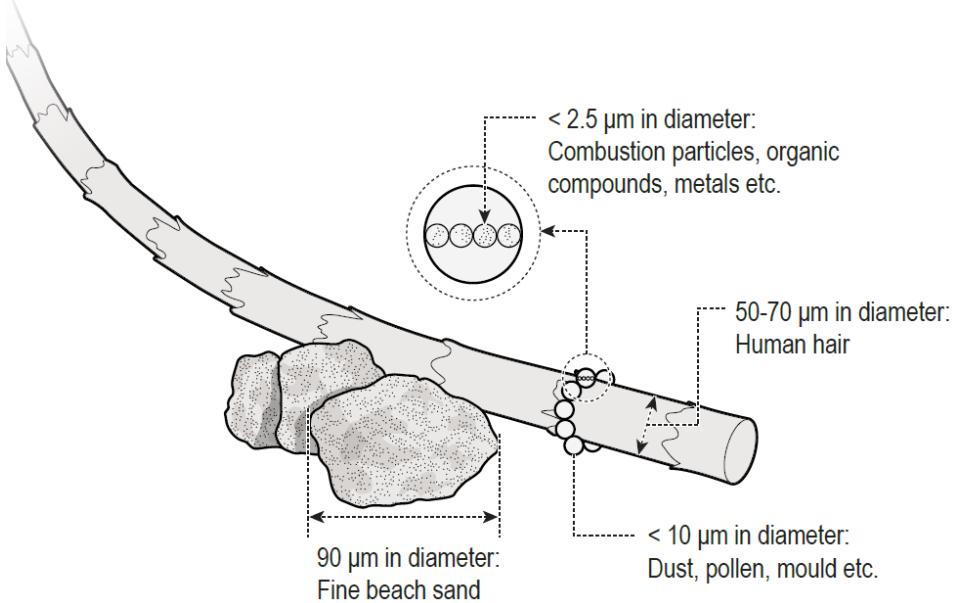

Respirable crystalline silica (RCS) is fine dust containing silica particles small enough to be inhaled deep into the lungs. Silica is a natural component of many materials including:

- Sand, soil, granite, sandstone

- Concrete, mortar, brick, tiles

- Engineered stone (artificial stone benchtops, up to 95% silica)

When these materials are cut, ground, drilled, crushed, or demolished, silica dust is generated.

Breathing silica dust causes silicosis (incurable lung disease), lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease.

High-Risk Construction Activities

Dry cutting/grinding/drilling:

- Concrete, masonry, brick, tiles

- Engineered stone (kitchen benchtops, bathroom vanities)

- Natural stone, sandstone

- Asphalt, roadways

Abrasive blasting:

- Using sand or silica-containing abrasives

Demolition:

- Concrete structures

- Brick and masonry buildings

Tunneling and excavation:

- Rock containing silica

Exposure Standard

WHS Regulation 50:

- 0.05 mg/m³ (8-hour time-weighted average)

The TWA must be adjusted for shifts longer than 8 hours or weeks longer than 40 hours, and must not be adjusted upwards.

This is a very small amount—effective dust control essential.

Who Has Duties?

PCBUs

Must:

- Identify if silica dust generated

- Assess risks of exposure

- Implement dust control measures following hierarchy of control

- Conduct air monitoring

- Provide health monitoring

- Provide information and training

- Keep exposure records

Designers, Manufacturers, Suppliers

Must:

- Design plant/processes to minimize silica dust

- Provide information on silica content

- Include dust control features in equipment

Risk Management Process

1. Identify Hazards

Check if materials contain silica:

- Concrete, brick, stone, tiles (assume contain silica)

- Engineered stone (very high silica content)

- Safety Data Sheets for manufactured products

- Natural stone and rock

Identify dust-generating activities:

- Cutting, grinding, drilling, sanding

- Demolition, breaking, crushing

- Dry sweeping of silica-containing dust

2. Assess Risks

Consider:

- Silica content of material (engineered stone = extreme risk)

- Type of activity (dry cutting worse than wet)

- Duration and frequency of exposure

- Enclosed vs. open-air work

- Number of workers exposed

Risk Indicators:

- Visible dust clouds

- Dust settling on surfaces

- Workers coughing or irritated

3. Control Risks: Hierarchy of Control

Level 1: Elimination

- Order pre-cut materials (no on-site cutting required)

- Use alternative materials (lower silica content)

- Design out need for cutting/modification

Example: Pre-fabricated concrete panels eliminate on-site cutting.

Level 2: Substitution

- Substitute lower-silica alternatives where possible

- Use non-silica abrasives for blasting

Example: For certain applications, use low-silica aggregate concrete.

Level 2: Engineering Controls (CRITICAL)

Engineering controls are the primary defense against silica dust:

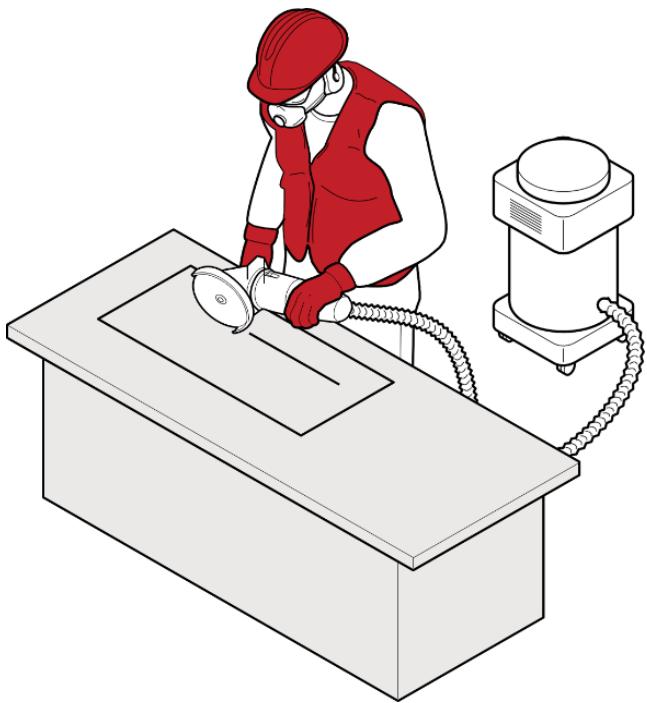

On-Tool Water Suppression:

- Continuously supplies water to cutting/grinding point

- Binds dust before it becomes airborne

- Mandatory for most silica work

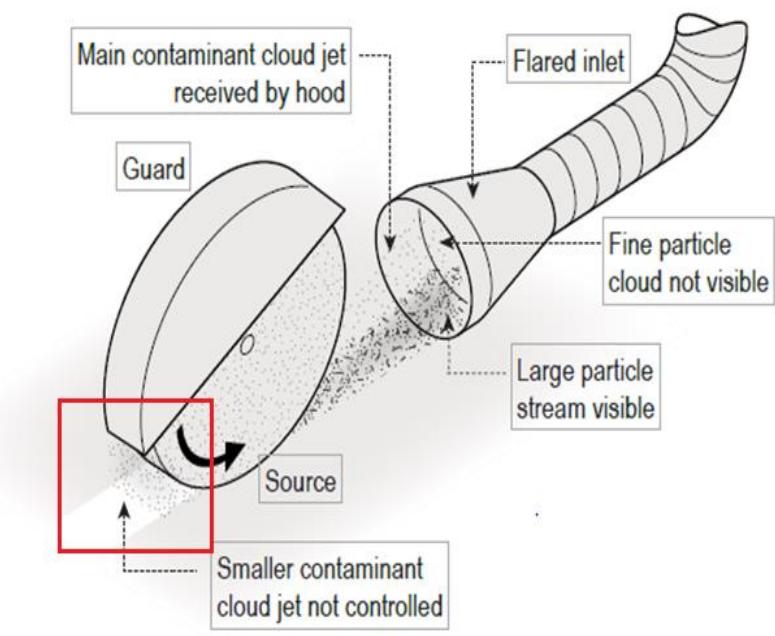

On-Tool Dust Extraction:

- Captures dust at source via vacuum system

- HEPA-filtered vacuum (H or M-class)

- Effective for drilling and some grinding

Combined Water + Extraction:

- Most effective control

- Example: Wet-cutting saw with vacuum shroud

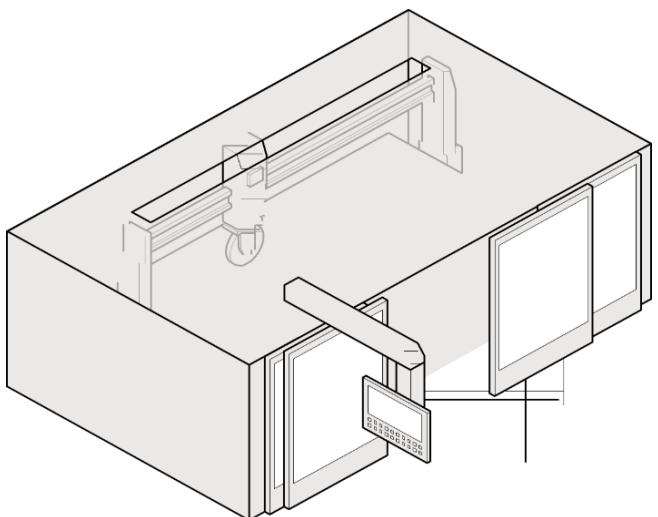

Ventilation:

- Local exhaust ventilation for enclosed work

- Natural ventilation for outdoor work (still requires other controls)

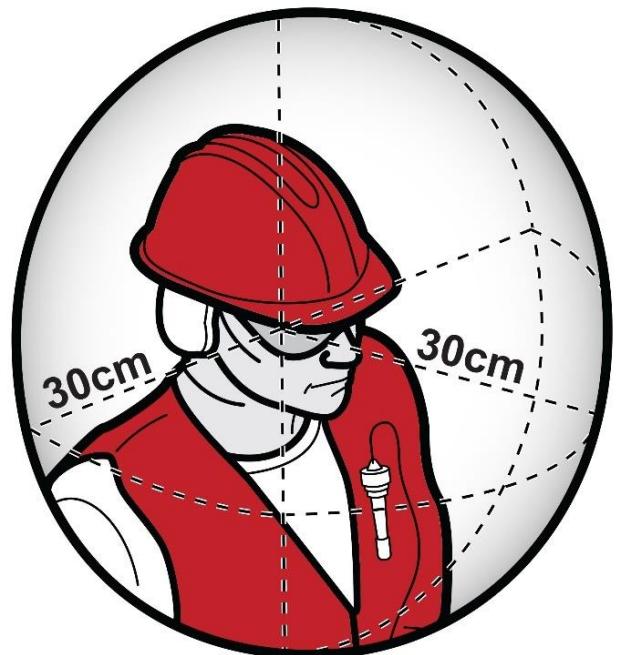

Isolation:

- Separate cutting area from other workers

- Exclusion zones during high-dust activities

- Enclose dust-generating processes

Level 3: Administrative Controls

- Limit time workers exposed to dust

- Rotate workers to reduce individual exposure

- Safe work procedures and Safe Work Method Statements

- Regular housekeeping (wet methods or HEPA vacuum only—never dry sweep)

- Training on silica risks and controls

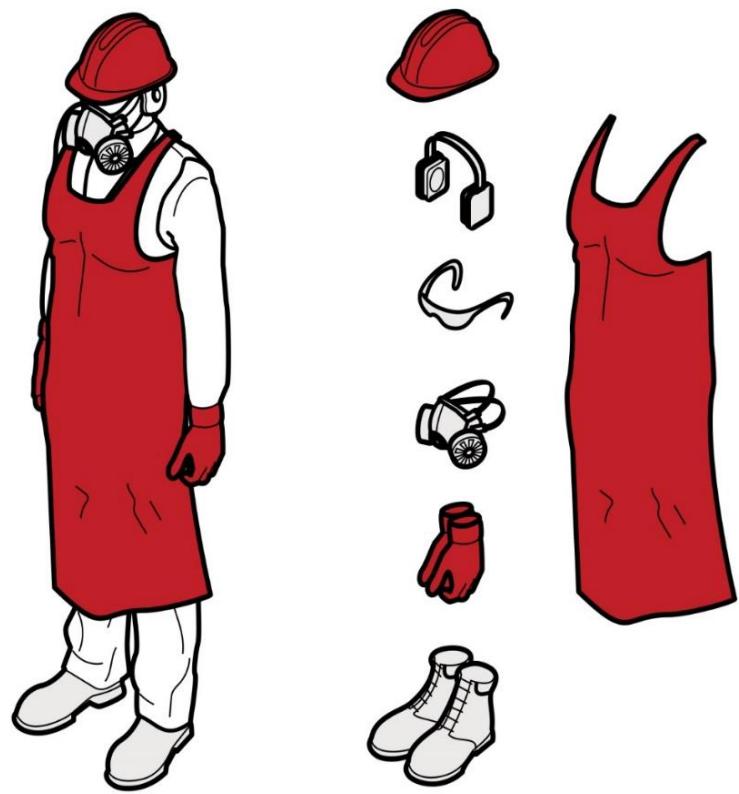

Level 3: Personal Protective Equipment

Never rely on PPE alone. Engineering controls must be primary.

Respiratory Protection:

- P2 or P3 respirators (disposable or reusable)

- Must be fit-tested to individual worker

- Quantitative fit testing required

- Replace when breathing resistance increases

For high-risk work (e.g., engineered stone):

- Powered air-purifying respirators (PAPR)

- Supplied-air respirators

Other PPE:

- Safety glasses/goggles

- Hearing protection (tools generate noise)

- Work clothing (changed regularly, not taken home)

4. Maintain and Review

- Inspect and maintain water suppression systems daily

- Test dust extraction equipment regularly

- Replace vacuum filters as needed

- Check respirators before each use

- Conduct air monitoring

- Review controls after incidents

Engineered Stone—Specific Requirements

Extremely High Risk: Engineered stone contains up to 95% silica. Special controls required.

Mandatory Controls:

- On-tool water suppression for all cutting, grinding, drilling

- On-tool dust extraction where water alone insufficient

- Respiratory protection (P2/P3 minimum, PAPR recommended)

- Health monitoring for all workers

Recommended Controls (Best Practice):

- Silica Dust Control Plan (highly recommended tool for ongoing management)

Prohibited Practices:

- Dry cutting (without water suppression)

- Using compressed air for cleaning

- Dry sweeping

Air Monitoring

When Required:

- Uncertain if exposure exceeds standard

- To verify control effectiveness

- After changing work methods or controls

- Regularly for high-risk work (engineered stone)

- Baseline Air Monitoring: Recommended when commencing work with engineered stone to establish exposure levels.

Who Conducts Monitoring:

- Competent person (occupational hygienist)

- Personal air samplers worn by workers

- Samples analyzed by NATA-accredited laboratory

Results:

- If exposure exceeds 0.05 mg/m³, immediate action required

- Improve controls, re-monitor to confirm effectiveness

- Keep records for 30 years

Health Monitoring

When Required (WHS Reg 56)

Health monitoring mandatory if worker:

- Carries out ongoing work with silica materials, AND

- Uses powered tools or equipment, OR

- Is at risk of exposure exceeding 0.05 mg/m³

This includes:

- All workers cutting, grinding engineered stone

- Workers regularly cutting/grinding concrete, brick, stone

- Abrasive blasters using silica abrasives

What Health Monitoring Involves

- Medical history and examination

- Respiratory function tests (spirometry)

- Chest X-ray or CT scan (baseline and periodic)

- Conducted by qualified medical practitioner

- Records kept for 30 years

Worker Rights:

- Access to own health records

- Confidential medical information

- No cost to worker

See Health Monitoring for details.

Silica Dust Control Plan

For ongoing silica work, prepare written plan including:

- Tasks that generate silica dust

- Risk assessment results

- Control measures for each task

- Air monitoring schedule

- Health monitoring requirements

- Training requirements

- Review schedule

Practical Construction Example

Scenario: Cutting concrete slabs for plumbing penetrations

Hazard Identification

- Concrete contains crystalline silica

- Dry cutting generates respirable dust

- Multiple cuts required daily

- Workers exposed throughout project

Risk Assessment

- High risk: Regular exposure, high dust generation

- Multiple workers involved

Controls Implemented

Engineering:

- Wet-cutting saw with continuous water supply

- On-tool extraction for handheld grinder (backup)

- Work outdoors where possible (ventilation)

- Exclusion zone 3 meters around cutting

Administrative:

- SWMS prepared for silica work

- Trained operators only

- Wet methods for cleanup (no dry sweeping)

- Work clothing changed daily

PPE:

- P2 respirators (fit-tested to each worker)

- Safety glasses

- Hearing protection

- Gloves

Monitoring:

- Air monitoring conducted (initial and periodic)

- Results below 0.05 mg/m³ (controls effective)

- Health monitoring arranged for all exposed workers

Review

- Daily check: Water system functioning

- Weekly: Inspect equipment, confirm procedures followed

- After project: Review effectiveness, update controls for next project

Clearance and Cleanup

After Silica Dust Work:

Never:

- Dry sweep or use compressed air

- Allow dust to accumulate

- Use standard shop vacuums (spread dust)

Always:

- Wet wipe surfaces

- Use HEPA-filtered vacuum (H or M-class)

- Dispose of waste properly (sealed bags)

- Clean work clothing (commercial laundry, not home)

Information and Training

Workers must know:

- Health effects of silica dust (silicosis, lung cancer)

- How to identify silica-containing materials

- Dust-generating activities

- How to use control measures (water systems, extraction, PPE)

- Importance of health monitoring

- Never remove or bypass controls

Summary of Key Requirements

For All Silica Work: ✓ Use water suppression or dust extraction ✓ Never dry cut, grind, or drill ✓ Use appropriate respiratory protection ✓ Conduct air monitoring ✓ Provide health monitoring ✓ Train all workers

For Engineered Stone: ✓ All above controls PLUS ✓ Mandatory water + extraction ✓ Higher-level respiratory protection (PAPR recommended) ✓ Silica Dust Control Plan ✓ Regular air monitoring