Managing Risk of Falls at Workplaces

Falls from Height - Major Hazard

Falls from height are the leading cause of death and serious injury in construction.

Common Fall Scenarios:

- Falling from roofs, edges of floors/slabs

- Through fragile surfaces (skylight, roof sheets)

- From ladders, scaffolding, elevated work platforms

- Into excavations or voids

- From structures during erection/demolition

Falls from even low heights (< 2 meters) can cause serious injury or death, especially if landing on hard surfaces or striking objects.

When is Work at Height High-Risk Construction Work?

Work involving risk of fall > 2 meters requires Safe Work Method Statement.

Examples:

- Roof work on houses (typically 3-4m from ground)

- Working on slabs/floors of multi-storey buildings

- Scaffolding erection/use

- Working from ladders >2m

Who Has Duties?

PCBUs

Must:

- Eliminate risks of falls (where reasonably practicable)

- If not practicable to eliminate, minimize risks

- Provide fall protection systems

- Ensure workers trained in fall protection use

- Prepare SWMS for work >2m fall risk

Designers

Must design structures to:

- Eliminate or minimize fall risks during construction, use, maintenance, demolition

- Include permanent anchorage points for maintenance access

- Provide safe access for ongoing maintenance

Workers

Must:

- Follow safe work procedures and SWMS

- Use fall protection equipment as instructed

- Report damaged or defective equipment

- Not remove or bypass safety systems

Hierarchy of Control for Falls

Level 1: Elimination

Most Effective: Remove the need to work at height.

Methods:

- Pre-fabricate at ground level, lift into position

- Design roof trusses on ground, crane to roof

- Use tilt-up construction (walls erected from ground)

- Remote inspection (drones, cameras) instead of physical access

Example: Pre-fabricate roof sections complete with battens and flashing on ground. Crane to roof as complete units, eliminating most work at heights.

Level 2: Minimize Risk - Passive Fall Prevention

If elimination not practicable, prevent falls using passive systems (physical barriers).

Guardrails/Edge Protection:

- Top rail at 900-1100mm

- Mid-rail

- Toe board (minimum 100mm)

- Strong enough to withstand leaning/impact

- No gaps > 250mm

Advantages:

- Protects everyone in area (not just those wearing harnesses)

- No special training required

- Does not rely on worker behavior

- Most reliable control

Applications:

- Slab edges during construction

- Roof edges

- Scaffold platforms

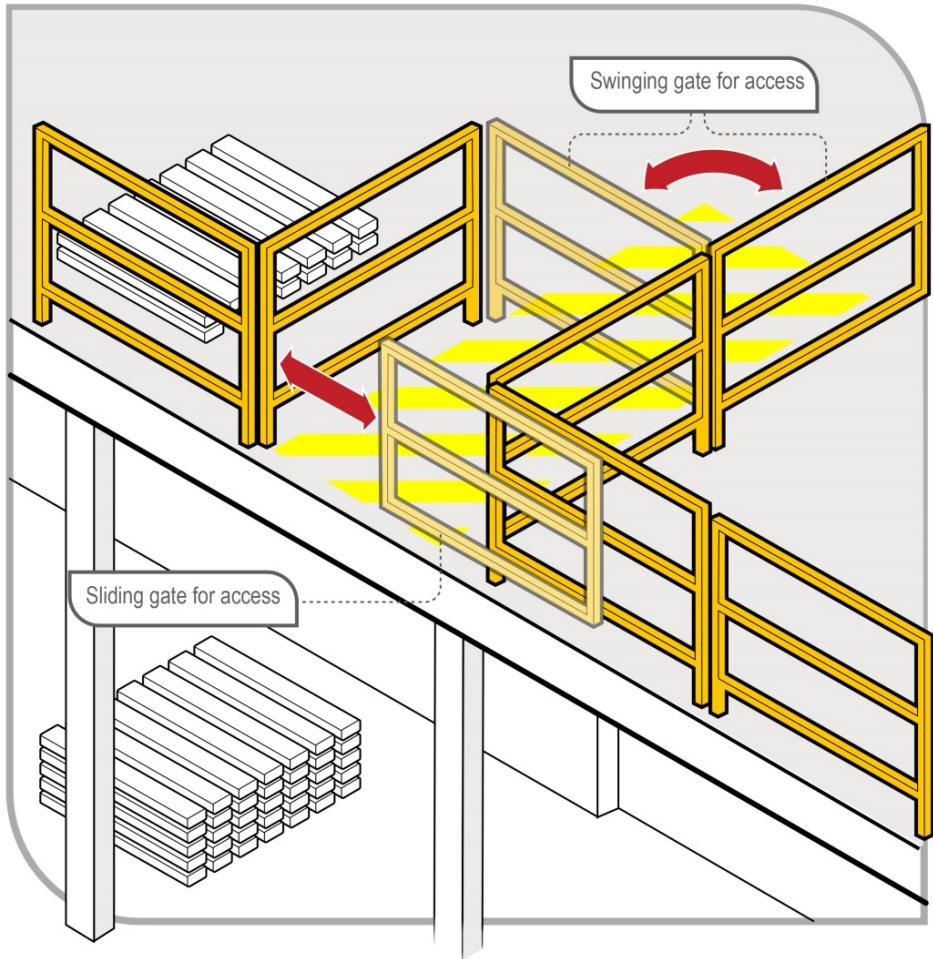

- Mezzanine floors

- Stair openings

Figure: Mezzanine floor barrier

Figure: Mezzanine floor barrier

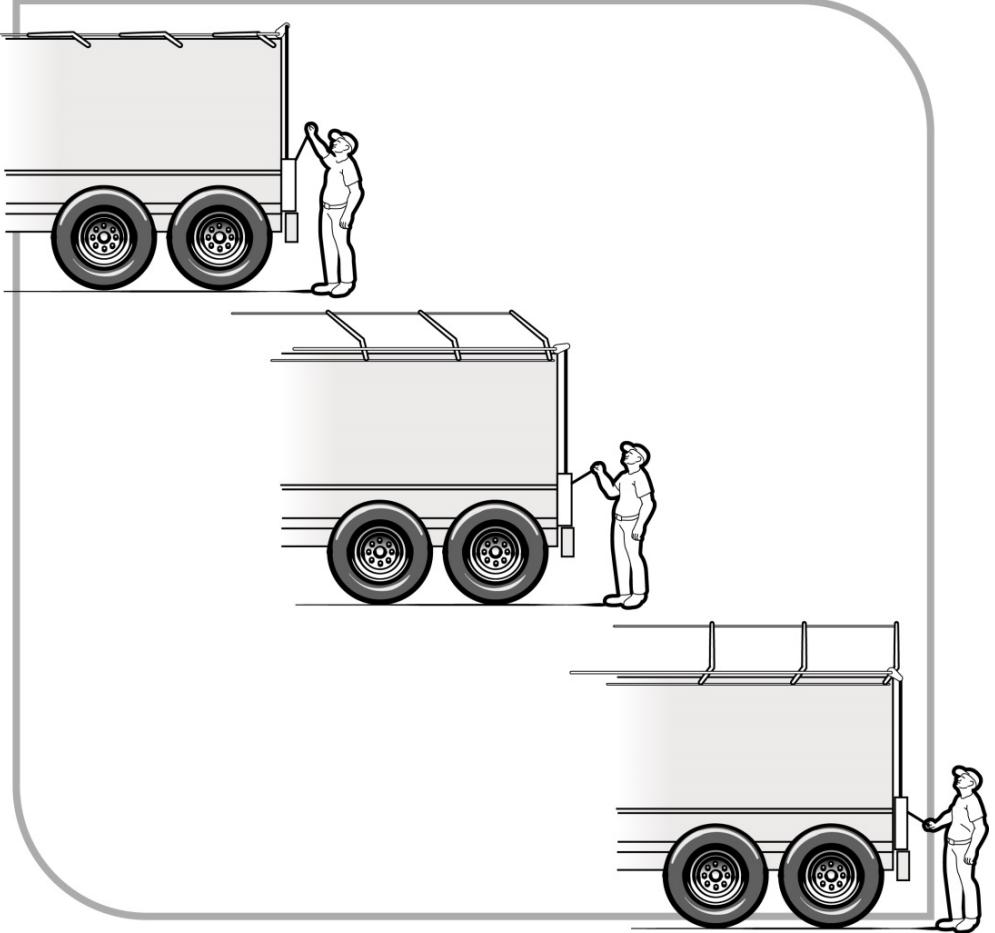

Figure: Guardrails installed on plant for safe access

Figure: Guardrails installed on plant for safe access

Perimeter Safety Screens:

- Mesh attached to structure perimeter

- Catches falling workers and materials

- Used on multi-storey construction

Safety Mesh/Netting:

- Under fragile roof materials

- Below overhead work (catches falling workers/materials)

- Must be installed by competent person

Covers Over Penetrations:

- Secure covers for floor openings, shafts

- Must support weight of person walking on it

- Clearly marked ("HOLE - DO NOT REMOVE COVER")

Guardrails and edge protection are more reliable than fall arrest systems. Use wherever reasonably practicable.

Level 2: Minimize Risk - Work Positioning and Restraint

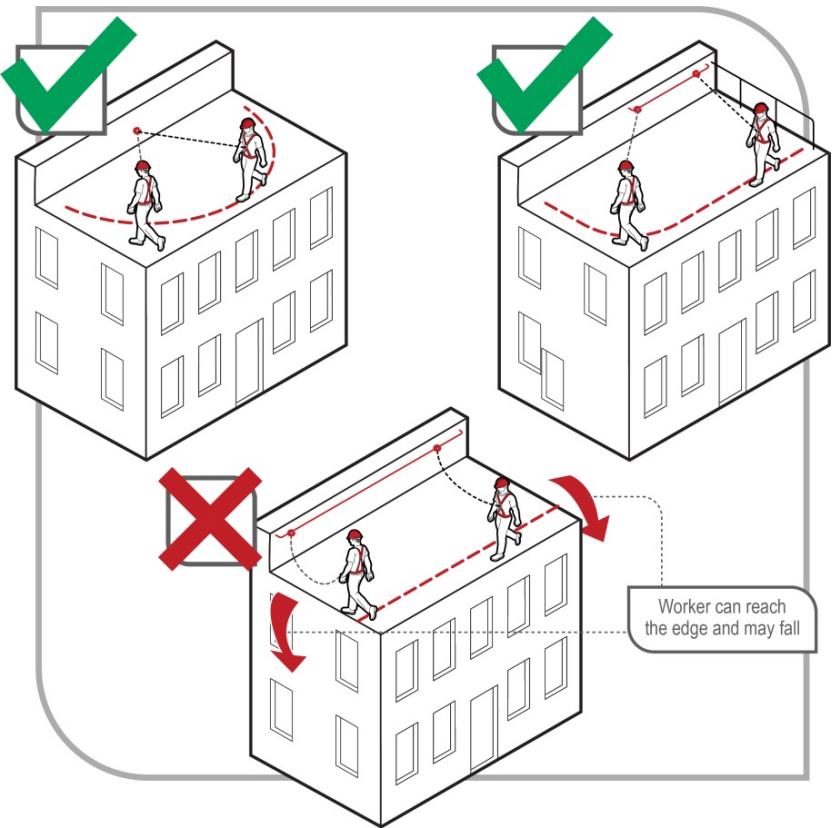

Fall Restraint Systems: Physically prevents worker from reaching fall edge.

Components:

- Anchorage point (rated, tested, certified)

- Full-body harness

- Lanyard (adjustable, limits travel to prevent reaching edge)

Advantage:

- Prevents fall (worker cannot reach edge)

- No fall arrest forces

Limitation:

- Work area restricted

- May not be practicable for large areas

Figure: Restraint technique - prevents reaching the fall edge

Figure: Restraint technique - prevents reaching the fall edge

Example: Worker on roof with harness connected to ridge anchor. Lanyard length prevents reaching eaves.

Level 3: Minimize Risk - Fall Arrest Systems

When Used: Where higher-level controls not reasonably practicable.

Fall arrest stops a fall but does not prevent it. Significant injury risk from fall itself, suspension trauma, and arrest forces.

Components:

1. Anchorage Point:

- Must withstand 15kN (static) or 12kN (if engineered)

- Certified and inspected

- Located to minimize free-fall distance and swing

2. Full-Body Harness:

- AS/NZS 1891.1 compliant

- Correctly fitted to individual

- Dorsal (back) attachment point for fall arrest

3. Connecting Device:

- Shock-absorbing lanyard: Reduces arrest forces

- Self-retracting lifeline (SRL): Arrests falls quickly, minimal free-fall

- Must be compatible with harness and anchorage

4. Rescue Plan:

- Method to rescue fallen worker within 6 minutes

- Suspension trauma can be fatal

- Rescue equipment and trained personnel

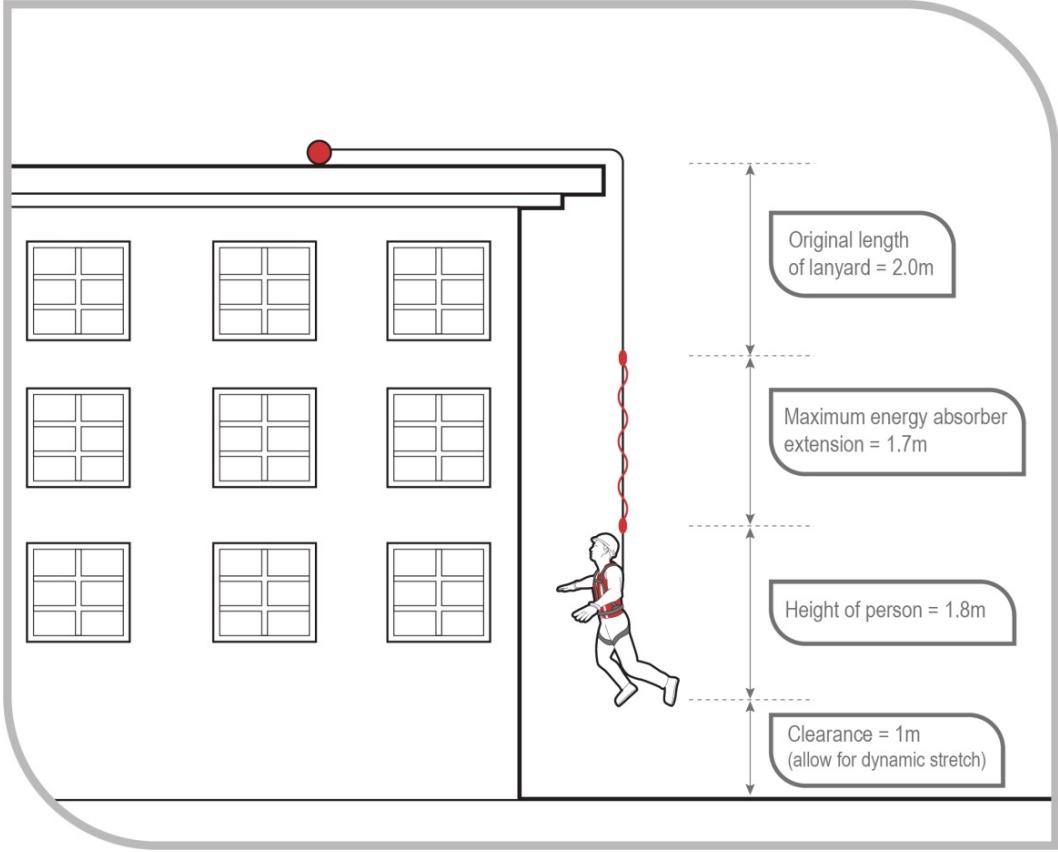

Critical Requirements:

- Maximum free-fall distance 2 meters (preferably <1m)

- Minimum clearance below (calculate fall distance + lanyard extension + worker height + safety margin)

- Regular inspection (before each use)

- Training in correct use

- Compatible equipment (not mixing brands without verification)

Figure: Calculating total fall distance vs clearance required

Figure: Calculating total fall distance vs clearance required

Example Calculation:

- Worker height: 1.8m

- Free-fall: 1m

- Lanyard extension during arrest: 1.2m

- Safety margin: 1m

- Minimum clearance required: 5m below anchor point

Level 3: Administrative Controls and PPE

Used in conjunction with fall protection systems, not alone:

- Training in fall protection use

- SWMS for work at heights

- Permits for roof access

- Competent supervision

- Weather restrictions (wind, rain, ice)

- PPE (hard hats, safety boots)

Specific Fall Risks and Controls

Roof Work

Fragile Roofs: Materials that won't support person's weight (old corrugated iron, skylight, fiber-cement).

Controls:

- Install walkways/crawl boards (distribute weight)

- Safety mesh under fragile areas

- Edge protection at roof perimeter

- Fall arrest if mesh/rails not practicable

- Never rely on roof material alone

Pitched Roofs:

- Scaffolding with edge protection for installation/maintenance

- Roof brackets and planks (not <30 degrees pitch)

- Fall arrest for steep pitches

- Consider weather (rain, ice makes surfaces slippery)

Ladders

Ladders are for Access, Not Workplaces: Use ladders only for:

- Short duration, low-risk work

- Access to/from another level

Requirements:

- Industrial-rated (not domestic)

- Inspected before use (check rungs, stiles, feet)

- Secured (tied off top and bottom, or footed by second person)

- Correct angle (1:4 ratio - 1m out for every 4m up)

- Extend 1m above landing platform

- Three-point contact (two hands, one foot or two feet, one hand)

- Face ladder when ascending/descending

- Don't carry loads (use tool belt or hoist materials)

When Not to Use Ladders:

- Prolonged work (use scaffold/platform)

- Heavy or awkward loads

- Work requiring two hands

- Work above 2 meters (where scaffold practicable)

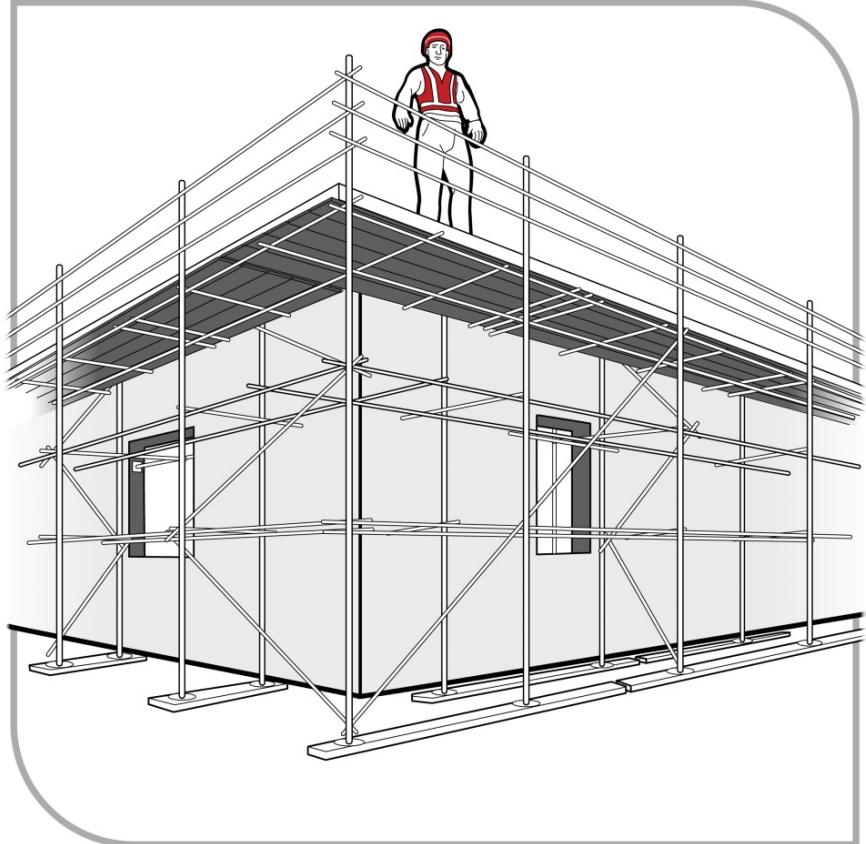

Scaffolding

Advantages:

- Large work platform

- Edge protection built-in

- Stable base for materials

- Suitable for prolonged work

Requirements:

- Erected by licensed scaffolder

- Designed for loads (workers + materials)

- Inspected before use and regularly

- Tagged (green = safe, red = unsafe - DO NOT USE)

- Tied to structure (prevents collapse/movement)

- Edge protection (toe boards, mid-rails, top rails)

- Safe access (internal ladder, stairs)

- Level, stable base (base plates, mud sills)

Figure: Perimeter scaffold with guardrails, mid-rails, and toe-boards

Figure: Perimeter scaffold with guardrails, mid-rails, and toe-boards

Inspection:

- Before each shift

- After weather events (strong wind, rain)

- After any modifications

- By competent person

Users Must:

- Check tag before using

- Not modify scaffold

- Not overload

- Not remove edge protection

- Report damage immediately

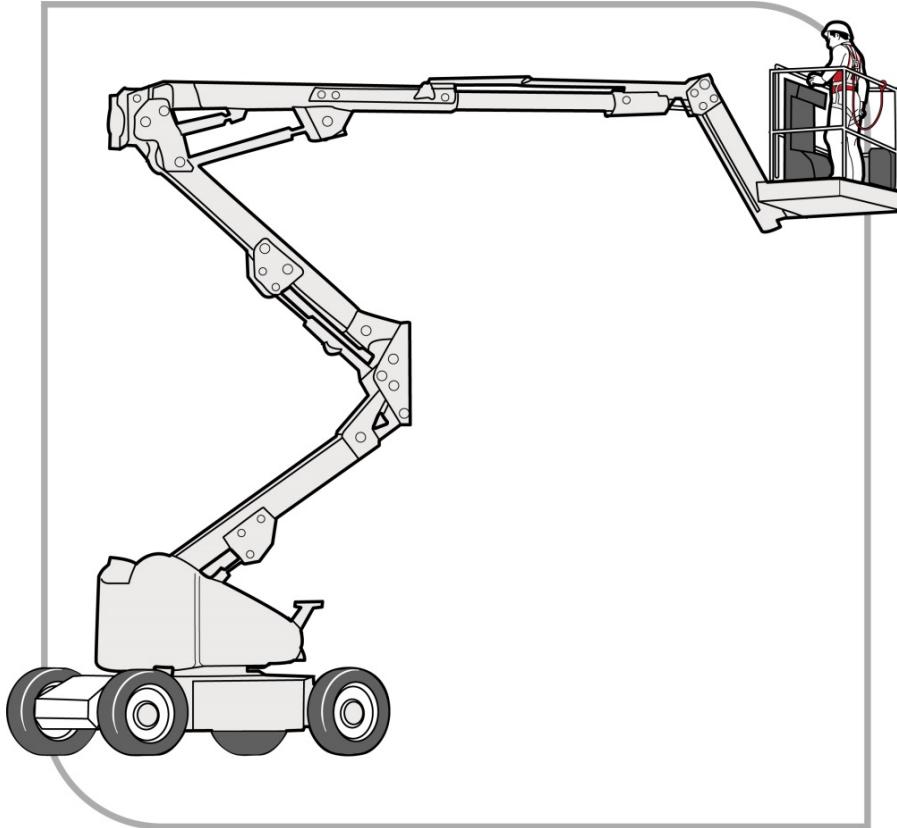

Elevated Work Platforms (EWP)

Types:

- Scissor lifts (vertical)

- Boom lifts (articulated/telescopic)

Figure: Boom-type elevating work platform

Figure: Boom-type elevating work platform

Safety Requirements:

- Licensed operator for boom-type (boom length of 11 metres or more)

- Pre-start inspection

- Guardrails on platform (intact, no gaps)

- Harness required for boom-type (anchor to platform, not structure)

- Level, stable ground

- Use outriggers if fitted

- Avoid overhead hazards (powerlines, structures)

- Lower platform when traveling

Fall Protection:

- Scissor lifts: Guardrails (harness generally not required)

- Boom lifts: Guardrails + harness anchored to platform

Excavations

Risk: Falling into excavations (same as falling from height).

Controls:

- Edge protection (barriers, guardrails) around excavation perimeter

- Covers over narrow trenches (must support traffic loads if applicable)

- Warning signs

- Adequate lighting

- Safe access/egress (ladders every 15m)

See Excavation Work for detailed guidance.

Rescue Procedures

Suspension Trauma: Hanging motionless in harness after fall can cause blood to pool in legs, leading to unconsciousness and death within 6-15 minutes.

Rescue Plan Must Include:

- Method to reach and rescue fallen worker

- Equipment (rescue lines, descent devices, EWP, crane)

- Trained rescue personnel

- Communication method (phone, radio)

- Contact emergency services (000)

- First aid and medical treatment

- Target rescue time: <6 minutes

While Awaiting Rescue:

- Conscious worker should move legs (pumping action to maintain blood flow)

- If suspension relief straps available, deploy and stand in them

Practical Construction Example

Scenario: Installing roof sheeting on single-storey warehouse (eaves 5m from ground)

Hazard Identification

- Fall from roof edge (5m fall = fatal)

- Fragile roof lights (not yet installed)

- Weather (wind, rain)

Risk Assessment

- Extreme risk: Fall from 5m onto concrete = likely death or serious injury

Controls Implemented

Engineering (Level 2):

- Perimeter edge protection installed before roof work starts (guardrails on all edges)

- Safety mesh installed under areas where roof lights will be fitted

- Scaffolding with edge protection on one side for material delivery and safe access

Administrative:

- SWMS prepared and reviewed with workers

- Only competent roofers permitted on roof

- Work stopped if wind >30 km/h or rain

- Exclusion zone on ground (5m from building perimeter)

PPE:

- Hard hats (falling objects from edge)

- Safety boots, gloves

- Fall arrest harness (backup - edge protection is primary control)

Result

Roof installed safely. Edge protection prevented any falls. Mesh provided backup protection at roof light penetrations.