Hazardous Manual Tasks

What are Hazardous Manual Tasks?

Hazardous manual tasks are tasks that require a person to lift, lower, push, pull, carry or otherwise move, hold or restrain any person, animal or thing that involves risk of musculoskeletal disorder (MSD).

Common Construction Examples:

- Lifting and carrying materials (bags of cement, timber, bricks)

- Placing and tying reinforcement steel (rebar)

- Laying pavers or blocks

- Operating jackhammers or compactors (vibration)

- Repetitive nail gunning or screwing

- Prolonged awkward postures (overhead work, confined spaces)

What are Musculoskeletal Disorders?

MSDs are injuries or disorders of muscles, tendons, ligaments, joints, nerves, blood vessels or related soft tissues.

Common MSDs in Construction:

- Back injuries (strains, disc problems)

- Shoulder injuries (rotator cuff, bursitis)

- Neck pain

- Knee problems

- Hand/wrist injuries (carpal tunnel syndrome, tendonitis)

MSDs develop over time through repeated exposure. Early symptoms (discomfort, aching) indicate risk and need addressing.

Risk Factors for MSDs

Characteristics of Hazardous Manual Tasks

1. Repetitive or Sustained Force

- Lifting heavy loads repeatedly

- Sustained gripping or pinching

- Repetitive movements (hammering, cutting)

2. High or Sudden Force

- Lifting very heavy items

- Jerking or snatching loads

- Catching falling objects

- Impact forces (jackhammer vibration)

3. Repetitive Movement

- Performing same movement repeatedly

- Example: Repetitive bricklaying, screw driving, grinding

4. Sustained or Awkward Postures

- Bending forward (tying steel, placing pavers)

- Reaching overhead (ceiling work)

- Kneeling or squatting (tiling, waterproofing)

- Twisting (turning with load)

- Working in confined spaces

5. Exposure to Vibration

- Hand-arm vibration (grinders, drills, breakers)

- Whole-body vibration (operating heavy plant)

Who Has Duties?

PCBUs

Must:

- Identify hazardous manual tasks

- Assess MSD risks

- Eliminate or minimize risks

- Consult with workers

- Provide information and training

- Review controls

Designers, Manufacturers, Suppliers

Must:

- Design to eliminate/minimize manual handling

- Consider weight, size, shape of products

- Provide handling information

Risk Management Process

1. Identify Hazardous Manual Tasks

Methods:

- Observe work activities

- Talk to workers (discomfort surveys)

- Review injury/incident reports

- Check design/planning documents

Construction-Specific Indicators:

- Materials supplied in heavy units (cement bags, pavers)

- Repetitive tasks (bricklaying, fixing)

- Confined or restricted work areas

- Overhead or below-knee work required

2. Assess Risks

When to Assess:

- When hazardous task identified

- Before introducing new tasks, equipment, layouts

- After MSD injuries reported

- When workers report discomfort

What to Consider:

- Loads: Weight, size, shape, stability

- Actions: Postures, movements, duration, frequency

- Workspace: Layout, heights, access, lighting

- Environment: Surfaces, weather, space constraints

- Worker: Training, experience, fatigue

3. Control Risks: Hierarchy of Control

Level 1: Elimination

- Eliminate need for manual task entirely

- Example: Pre-mixed concrete delivery eliminates mixing bags on-site

Level 2: Substitution/Engineering

Mechanical Aids:

- Forklifts, cranes, hoists for lifting

- Trolleys, wheelbarrows for transporting

- Conveyors for moving materials

- Elevated work platforms instead of ladders

Example: Use telehandler to lift pallet of bricks to upper level instead of manual carrying.

Redesign Task:

- Reduce weight/size of loads (smaller cement bags, lighter blocks)

- Improve layout (materials closer to work area)

- Adjust work heights (raise/lower to reduce bending)

- Provide better access (platforms, pathways)

Example: Store formwork materials at waist height on racks instead of on ground.

Use Tools and Equipment:

- Mechanical lifting devices

- Slide sheets or rollers

- Adjustable height benches

- Power tools to reduce force

Level 3: Administrative Controls

- Job rotation to vary tasks and postures

- Task pacing (rest breaks, varied work)

- Team lifting for heavy/awkward loads

- Training in safe lifting techniques

For loads that are heavy, awkward, or exceed individual capacity (risk assessed), use two or more workers. Coordinate lift with clear signals.

Level 3: PPE

PPE does not control manual handling risks. Focus on higher-level controls.

(Note: Supportive devices like back belts are not effective and not recommended)

4. Review Controls

Review when:

- Control measures not effective

- MSDs or discomfort reported

- Work processes change

- New equipment or layout

Practical Construction Examples

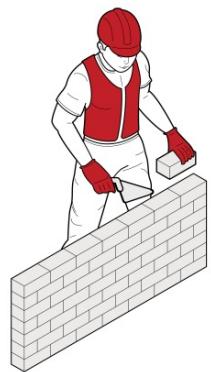

Example 1: Laying Concrete Blocks

Hazard:

- Blocks weigh 15-20kg each

- Repetitive lifting from ground level

- Bending and twisting

- Several hundred blocks per day

Controls:

Engineering:

- Deliver blocks on pallets with forklift

- Position pallet close to work area (reduce carrying distance)

- Elevate pallet on trestles to waist height (eliminate bending)

- Provide adjustable scaffold for working at height

Administrative:

- Job rotation (alternate between laying and other tasks)

- Two workers team-laying for speed and reduced individual load

- Adequate breaks

Result: Significantly reduced bending and twisting, load easier to grasp from waist height.

Example 2: Tying Reinforcement Steel

Hazard:

- Sustained bending and squatting

- Repetitive twisting motion (thousands per day)

- Awkward hand positions

Controls:

Engineering:

- Use clip-on bar ties instead of manual wire tying (faster, less repetitive)

- Battery-powered rebar tying gun (eliminates manual twisting)

- Work platforms to raise worker position where practicable

Administrative:

- Job rotation to reduce daily exposure

- Training in neutral postures

Result: Manual twisting eliminated, reduced bending time.

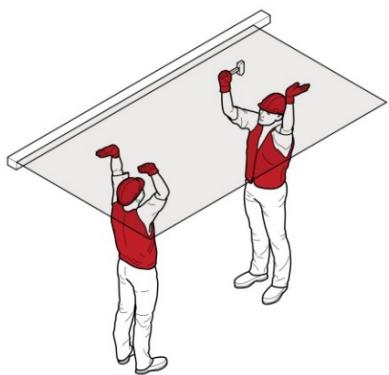

Example 3: Moving Plasterboard Sheets

Hazard:

- Sheets 2.4m x 1.2m, weight 20-30kg

- Awkward to handle (large, unwieldy)

- Carrying required (often up stairs/ladders)

Controls:

Engineering:

- Panel hoist/lifter to move and position sheets

- Storage racks at appropriate height

- Material hoist to upper floors (eliminate manual carrying up stairs)

Work Organization:

- Deliver materials as close to installation point as possible

- Two-person team for manual handling when hoist unavailable

Result: Eliminates most manual carrying, significantly reduces awkward postures.

Special Considerations

Working Overhead

Risks:

- Shoulder and neck strain

- Arm fatigue

- Difficulty controlling loads above head

Controls:

- Elevate work platform to bring work to chest/waist height

- Use mechanical aids (ceiling panel lifters)

- Limit duration of overhead work

- Provide armrests or supports

Working at Ground Level

Risks:

- Prolonged bending, kneeling, squatting

- Back and knee strain

Controls:

- Raise work height (platforms, adjustable benches)

- Knee pads for kneeling tasks

- Kneeling stools or creepers

- Vary postures regularly

Confined Spaces

Risks:

- Restricted postures

- Difficulty using mechanical aids

- Limited access for materials

Controls:

- Pre-assemble components outside confined space where possible

- Use smaller, lighter materials

- Provide adequate access for material delivery

- Limit time in confined space

Information and Training

Workers should be trained in:

- Recognizing hazardous manual tasks and MSD risks

- How to use mechanical aids and equipment

- Safe work practices for unavoidable manual tasks

- Importance of reporting discomfort early

- Warm-up and stretching (supplement to controls, not substitute)