Managing Risks of Plant

What is Plant?

Plant includes machinery, equipment, appliances, containers, implements and tools, and any component or fitting.

Construction Plant Examples:

- Mobile plant: Excavators, loaders, forklifts, trucks, cranes, elevated work platforms (EWP)

- Fixed plant: Concrete pumps, compressors, generators, scaffolding

- Power tools: Saws, grinders, drills, nail guns, welding equipment

- Pressure equipment: Air compressors, pressure vessels

- Lifting equipment: Cranes, hoists, lifting beams, slings

Common Plant Hazards

Mechanical hazards:

- Crush points, shear points, entanglement

- Ejected parts or materials

- Moving parts (blades, gears, belts, chains)

Non-mechanical hazards:

- Electricity

- Noise and vibration

- Heat, fire, explosion

- Hazardous substances (fumes, dust, hydraulic fluids)

Operational hazards:

- Rollover or tip-over

- Collision with workers, structures, other plant

- Falls from height (working on/near plant)

- Loads falling from height

Who Has Duties?

PCBUs

Must:

- Manage plant risks through risk management process

- Ensure plant safe for intended use

- Maintain plant in safe condition

- Provide information, training, supervision

- Ensure operators licensed/competent

- Register certain high-risk plant

Designers, Manufacturers, Suppliers, Installers

Must:

- Ensure plant designed, manufactured, supplied, installed without risks

- Provide safety information

- Test and commission before supply

High-Risk Work Licences

WHS Regulation requires licences for:

- Cranes: Bridge/gantry, derrick, portal boom, tower, vehicle loading

- Hoists: Materials hoists, personnel/materials hoists

- Forklifts: All classes

- Elevating work platforms (EWP): Boom-type (boom length of 11 metres or more)

- Rigging: Basic, intermediate, advanced

- Dogging: Directing crane operations, slinging loads

- Scaffolding: Basic, intermediate, advanced

- Pressure equipment: Boilers, turbines (in some jurisdictions)

Always verify operator licences before allowing operation. Licences available at Industrial Relations NSW

Risk Management for Plant

1. Identify Hazards

Throughout Plant Lifecycle:

- Design: Inherent hazards in design

- Purchase: Suitability for intended use

- Installation: Commissioning, structural support

- Operation: Normal use hazards

- Maintenance: Access, isolation, stored energy

- Decommissioning: Safe dismantling and disposal

2. Assess Risks

Consider:

- Potential injuries (severity and likelihood)

- Who is at risk (operators, other workers, public)

- When risks arise (operation, maintenance, emergencies)

- Existing control measures

3. Control Risks: Hierarchy of Control

Level 1: Elimination

- Eliminate need for plant

- Example: Pre-cast panels eliminate on-site formwork systems

Level 2: Substitution/Engineering

Purchase Safe Plant:

- Select plant with built-in safety features

- Example: Excavator with ROPS (rollover protective structure), proximity detection systems

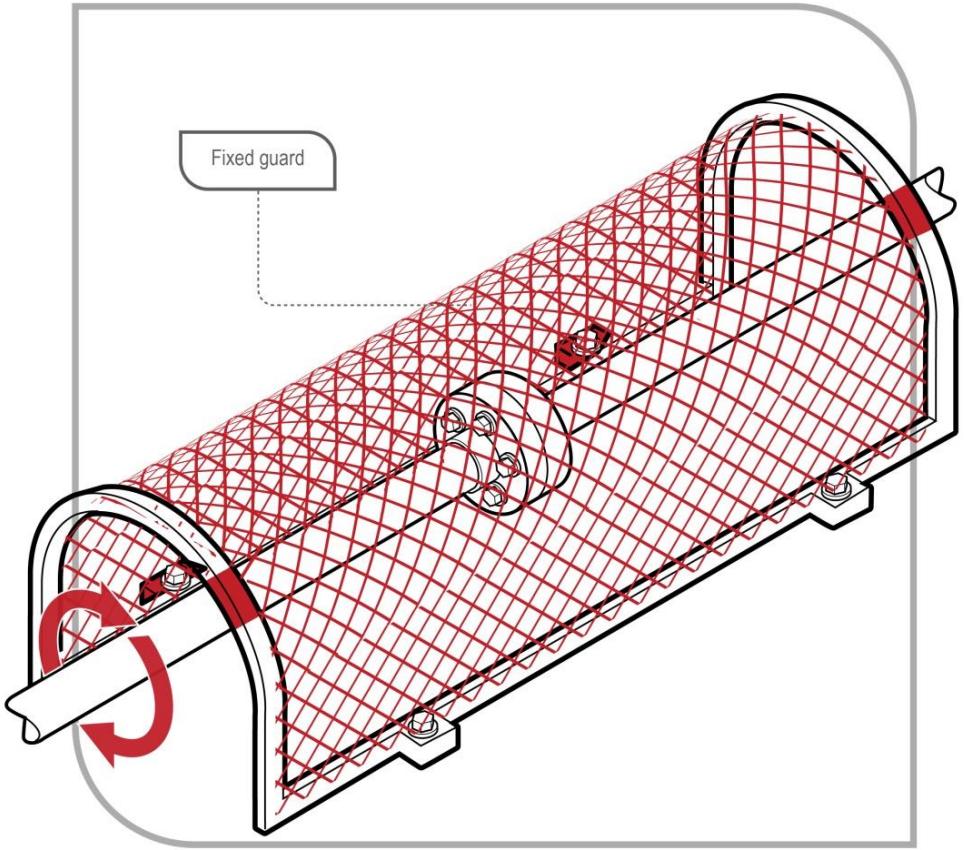

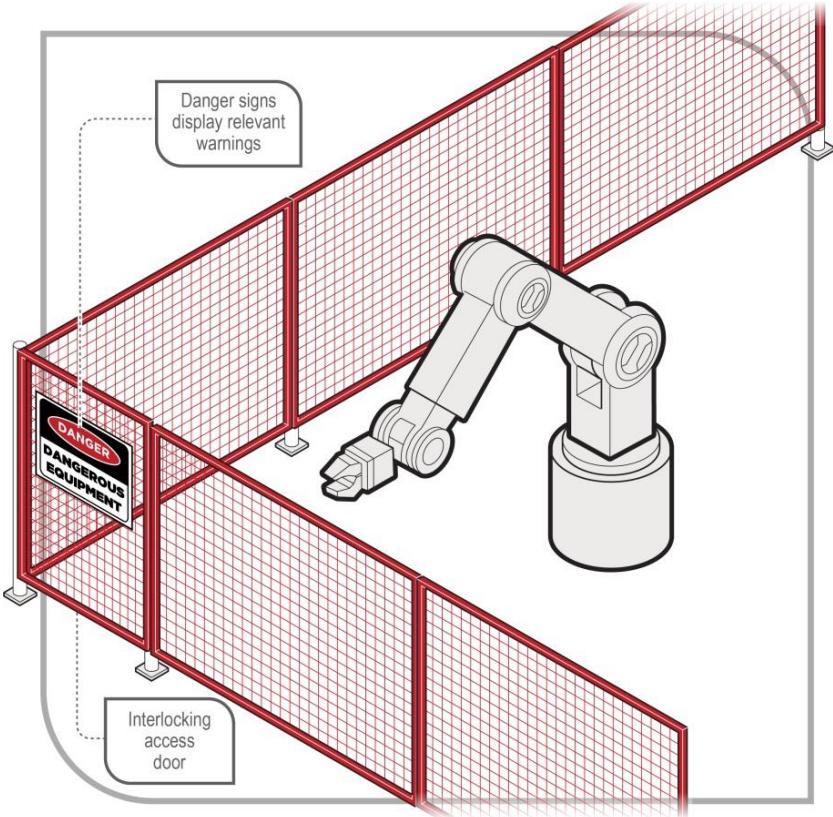

Guarding:

- Fixed guards (permanent barriers over dangerous parts)

- Interlocked guards (machine stops when guard opened)

Figure: Fixed guard preventing access to rotating shaft

Figure: Fixed guard preventing access to rotating shaft

Figure: Perimeter fence guard with fixed panels and interlocking access door

Figure: Perimeter fence guard with fixed panels and interlocking access door

- Adjustable guards (for different operations)

Example: Circular saw with retractable blade guard.

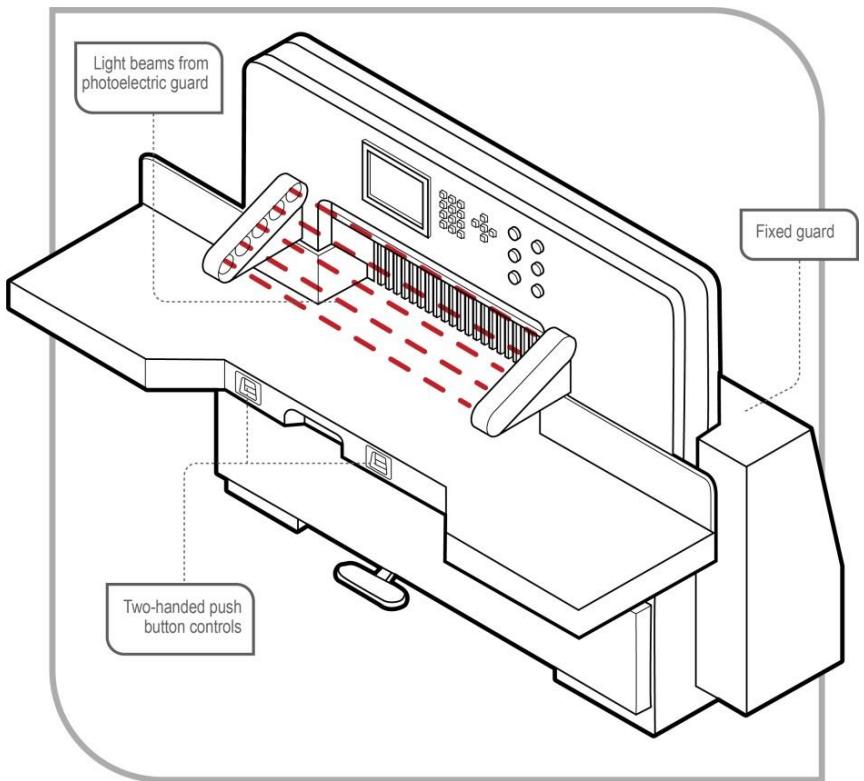

Operational Controls:

- Two-hand controls (both hands required, keeps hands away from danger zone)

- Hold-to-run controls (requires continuous activation)

- Proximity sensors (detects workers, stops machine)

Figure: Light curtain presence sensing system

Figure: Light curtain presence sensing system

- Speed limiters, load limiters

Emergency Stops:

- Readily accessible

- Clearly identified (red mushroom button)

- Stops machine immediately

Figure: Typical emergency stop button

Figure: Typical emergency stop button

Isolation:

- Lockout/tagout for maintenance

Figure: Example of lock-out with tag and multiple padlocks

Figure: Example of lock-out with tag and multiple padlocks

- Isolation of electrical, hydraulic, pneumatic, mechanical energy

- Dissipation of stored energy (springs, pressure, suspended loads)

Level 3: Administrative/PPE

- Safe work procedures

- Training and competency assessment

- Permits for high-risk plant operations

- Exclusion zones around operating plant

- Pre-start inspections

- PPE (hearing protection, hi-vis, hard hats, safety boots)

4. Maintain and Review

- Regular inspections (daily pre-start, periodic detailed)

- Preventive maintenance schedules

- Competent person conducts maintenance

- Record keeping

- Review after incidents or near-misses

Mobile Plant Safety

Separation of Vehicles and Pedestrians

Principle: Keep people and moving vehicles apart.

Controls:

- Dedicated pedestrian walkways (physically separated)

- Exclusion zones (barricades, signage)

- Traffic management plan

- Designated crossing points

- Spotters for reversing/confined areas

Example: Fenced walkways on construction site separate workers from vehicle routes.

Proximity Detection Systems

- Sensors detect workers near plant

- Alerts operator (visual/audible warning)

- May automatically stop or slow plant

- Useful for excavators, trucks with blind spots

Visibility

- Reversing cameras and monitors

- Mirrors and visibility aids

- High-visibility clothing for workers

- Flashing beacons on plant

- Reversing alarms

Reversing causes many injuries/fatalities. Eliminate reversing where possible, use spotters where unavoidable.

Rollover and Tip-Over Protection

- ROPS (rollover protective structures)

- Seatbelts (must be worn in ROPS-equipped plant)

- Operating within load ratings and stability limits

- Level, stable ground conditions

- Avoid slopes, edges, underground voids

Quad Bikes:

- From 11 October 2021, all new and imported second-hand general use quad bikes must be fitted with an operator protective device (OPD) to protect riders in the event of a rollover.

Lifting Operations

Before Lifting

- Plan the lift (load weight, lift path, hazards, exclusion zone)

- Select appropriate equipment (crane capacity, rigging)

- Inspect lifting equipment (cranes, slings, shackles)

- Brief all involved (crane operator, dogger, rigger, workers)

- Establish exclusion zone (no workers under suspended loads)

During Lifting

- Competent dogger directs crane operator

- Clear communication (hand signals, radio)

- Lift smoothly (no jerking or swinging)

- No workers under suspended load

- Secure load against wind, movement

Rigging and Slinging

- Calculate load weight

- Select correct slings (capacity, condition)

- Inspect slings before use (cuts, wear, damage)

- Use correct hitches and fittings

- Ensure load balanced and secure

Elevated Work Platforms (EWP)

Types:

- Scissor lifts (vertical)

- Boom lifts (articulated/telescopic)

- Mobile and stationary

Safety Requirements:

- Licensed operators (boom-type >11m vertical)

- Pre-start inspection

- Level, stable ground (use outriggers if fitted)

- Guardrails intact on platform

- Harnesses required for boom-type (anchor to platform)

- Avoid overhead hazards (powerlines, structures)

- Do not exceed platform load rating

- Lower platform when traveling

Maintain safe distances from powerlines. De-energize lines or use insulated/non-conductive equipment where work near powerlines unavoidable.

Scaffolding

Licensing:

- Basic scaffold licence: Scaffolds up to 4 meters

- Intermediate scaffold licence: All scaffolds

- Advanced scaffold licence: Design and inspection of scaffolds

Safety Requirements:

- Designed for loads (live load, wind load, materials storage)

- Erected by licensed scaffolder

- Inspected before use and regularly

- Tagged (green tag = safe to use, red tag = unsafe)

- Edge protection (toe boards, mid-rails, handrails)

- Safe access (ladders, stairs)

- Stable foundation (base plates, mud sills)

- Tied to structure (prevent movement/collapse)

See Construction Work for detailed scaffolding guidance.

Plant Registration

Certain high-risk plant must be registered:

- Cranes (various types)

- Hoists

- Pressure vessels and boilers

- Gas cylinders

Purpose: Ensures design verified, item inspected, safe to operate.

Inspections and Maintenance

Pre-Start Inspections (Daily)

Operator checks:

- Damage, leaks, loose parts

- Safety devices functioning (guards, emergency stops, alarms)

- Fluid levels, tire pressures

- Lights, indicators, controls

Record findings, report defects, do not use defective plant.

Periodic Inspections

Competent person conducts detailed inspections at intervals based on:

- Manufacturer recommendations

- Regulatory requirements (e.g., cranes, hoists)

- Risk assessment

Maintenance

- Follow manufacturer maintenance schedules

- Use qualified technicians

- Keep records (maintenance log)

- Ensure isolated before maintenance

- Test after repairs before returning to service

Practical Construction Example

Scenario: Using 20-tonne excavator for bulk excavation

Hazards Identified

- Rollover on sloped ground

- Striking workers or other plant

- Contact with underground services (gas, electricity)

- Noise and vibration

Controls Implemented

Engineering:

- Excavator equipped with ROPS and seatbelt

- Proximity detection sensors installed

- Reversing camera and alarm

Administrative:

- Licensed operator (verified before operation)

- Service location completed (Dial Before You Dig)

- Services marked on ground

- Exclusion zone 5 meters around excavator (barricades, signage)

- Traffic management plan (separate vehicle and pedestrian routes)

- Pre-start inspection completed and recorded

PPE (for nearby workers):

- Hard hats, hi-vis, safety boots, hearing protection

Maintenance

- Daily pre-start checks

- 250-hour service completed (recorded in log)

- Hydraulic hoses inspected (no leaks or damage)