Demolition Work

What is Demolition Work?

Demolition work means work to demolish or dismantle a structure, or part of a structure. This includes:

- Complete building demolition

- Partial demolition/strip-out

- Structural alterations

- Dismantling plant or structures

When Demolition is High-Risk Construction Work

Demolition work is High-Risk Construction Work (HRCW) requiring a Safe Work Method Statement if it involves the demolition of an element of a structure that is load-bearing or otherwise related to the physical integrity of the structure.

Major Hazards

Structural Collapse:

- Uncontrolled or premature collapse

- Workers trapped/crushed

Asbestos:

- Most buildings pre-2004 contain asbestos

- Disturbing asbestos releases deadly fibers

Falls from Height:

- Working on structures being demolished

- Floor/roof collapse

Underground Services:

- Striking gas, electricity, water during demolition

Falling Objects/Materials:

- Materials falling on workers or public below

- Debris ejected during demolition

Hazardous Substances:

- Lead paint, chemical residues

- Dust (silica, general)

Plant and Equipment:

- Excavators with hammers/shears

- Elevated work platforms

- Cranes

Before Demolition - Mandatory Requirements

1. Asbestos Assessment (WHS Reg 443)

Failure to identify asbestos before demolition is prohibited and extremely dangerous.

Requirements:

- Obtain or prepare asbestos register for structure

- If no register, presume asbestos present OR arrange inspection/sampling

- If asbestos identified, arrange licensed removal BEFORE demolition

- Provide asbestos information to all workers

See Asbestos for detailed guidance.

2. Structural Engineering Report

Required for:

- If as-built design documentation is not available

- If structure has been damaged or weakened (e.g. by fire)

- If plant is to be used on suspended floors

- Complex structures

- Where demolition method may affect stability

Report Must Cover:

- Structural details and construction method

- Sequence of demolition

- Special precautions required

- Method of preventing premature collapse

3. Service Disconnection

Before Demolition:

- Disconnect or isolate all services:

- Electricity (confirm de-energized)

- Gas (confirmed isolated by supplier)

- Water

- Telecommunications

- Sewerage

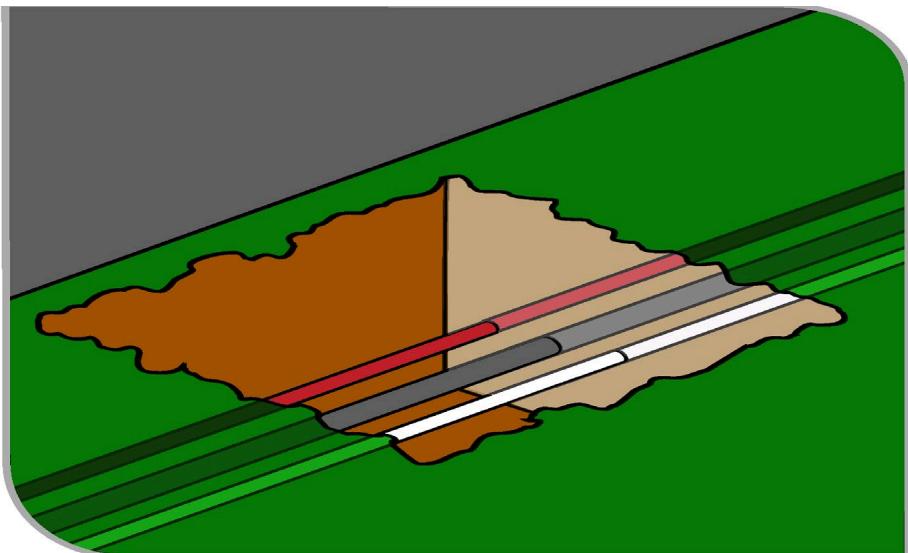

Underground Services:

- Locate using Dial Before You Dig

- Protect or remove before demolition

4. Demolition Plan

Plan Must Address:

- Sequence of demolition (what comes down first, last)

- Method (manual, mechanical, explosives)

- Structural stability during demolition

- Control of dust, noise, vibration

- Waste management

- Traffic management

- Protection of public and adjacent properties

- Emergency procedures

Methods of Demolition

Manual (Hand) Demolition

Process:

- Top-down, piece-by-piece removal

- Hand tools, small power tools

When Used:

- Small structures

- Where mechanical methods not suitable

- Hazardous materials present (asbestos)

- Adjacent structures must be protected

Hazards:

- Falls from height

- Manual handling

- Dust exposure

Mechanical Demolition

Equipment:

- Excavators with:

- Hydraulic breakers

- Pulverizers

- Shears

- Wrecking balls (rare, high risk)

When Used:

- Large structures

- Faster than manual

Hazards:

- Structural collapse

- Plant rollover

- Falling materials

- Dust

Controls:

- Competent operator

- Safe operating distance

- Exclusion zones

- Water suppression for dust

Explosive Demolition

Highly Specialized:

- Licensed shot firers

- Detailed engineering design

- Large exclusion zones

- Emergency services notification

Rarely Used: Except major structures in open areas.

Sequence of Demolition

General Principle: Top Down

- Remove roof first

- Then top floors

- Work down to ground

- Basement last

Maintain Stability:

- Remove non-structural elements first (windows, doors, fittings)

- Leave structural supports until last

- May require temporary bracing

Exceptions:

- Mechanical demolition may work differently (push over intact)

- Requires engineering assessment

Control Measures

Structural Stability

- Follow engineering report

- Install temporary supports if required

- Monitor for unexpected movement/cracking

- Establish exclusion zones (minimum 2 times building height for wire rope pulling/induced collapse)

Falls Prevention

- Edge protection on floors being demolished

- Safety mesh under fragile materials

- Scaffolding where needed

- Fall arrest systems (if edge protection not practicable)

See Falls.

Falling Objects

- Barricades and exclusion zones

- Chutes for dropping materials (enclosed)

- Screens on scaffolding

- Warning signs

- Hard hat areas

Never Drop Materials: Use controlled lowering or enclosed chutes.

Dust Control

- Water suppression (continuous wetting)

- Avoid dry sweeping or dry demolition

- Enclose work areas where practicable

- Respiratory protection for workers

See Silica Dust.

Public Protection

- Hoarding/fencing (minimum 1.8m high)

- Gantries/awnings over footpaths

- Traffic management

- Warning signs

- Security (prevent unauthorized entry)

Waste Management

Segregate Waste:

- Asbestos (special disposal)

- Recyclables (concrete, metal, timber)

- General waste

- Hazardous waste (lead paint, chemicals)

Asbestos Waste: See Asbestos - requires licensed disposal.

Dust and Debris:

- Prevent dust leaving site (water, barriers)

- Clean roads daily

- Cover trucks transporting waste

Practical Example

Scenario: Demolishing 2-storey brick house (built 1970s)

Pre-Demolition

1. Asbestos Assessment:

- Building inspection conducted

- Asbestos identified: roof (fibro cement), eaves, internal walls

- Licensed asbestos removalist engaged

- Asbestos removed (clearance certificate obtained)

- Register updated

2. Services:

- Electricity disconnected (verified)

- Gas isolated by supplier

- Water capped

- Underground services located

3. Demolition Plan:

- Method: Mechanical (excavator with pulverizer)

- Sequence: Roof, walls, slab, footings

- Dust control: Water sprays

- Exclusion zone: 10m from structure

- Public protection: 1.8m hoarding erected

During Demolition

Controls:

- SWMS reviewed with workers

- Licensed excavator operator

- Water tanker continuously wetting debris

- Exclusion zone barricaded

- Spotter monitoring for hazards

- Hard hats, respirators (P2), hi-vis, boots

- Waste segregated (brick to recycling, timber to bin)

Sequence:

- Non-structural: windows, doors, fixtures removed (manual)

- Roof sheeting and framing pulled down (excavator)

- Walls demolished section by section

- Slab broken up

- Footings removed

- Site leveled and cleaned

Result

Demolition completed in 3 days, no injuries, asbestos safely removed beforehand, dust controlled, waste recycled.