Construction Work

What is Construction Work?

Construction work means any work carried out in connection with the construction, alteration, conversion, fitting-out, commissioning, renovation, repair, maintenance, refurbishment, demolition, decommissioning or dismantling of a structure.

Common Examples:

- Building houses, commercial buildings, infrastructure

- Road and bridge construction

- Drainage and sewerage systems

- Demolition of structures

- Scaffolding erection

- Installing plant in structures

- Site preparation and earthworks

What is High-Risk Construction Work?

High-risk construction work (HRCW) requires a Safe Work Method Statement before work commences.

HRCW includes (WHS Reg 291):

- Work where risk of fall >2 meters

- Work on telecommunications towers

- Work near energized electrical installations (>440V or underground cables)

- Confined space work

- Demolition work

- Work involving disturbance of asbestos

- Work on/near pressurized gas distribution mains

- Diving work

- Work in/near water or other liquid (drowning risk)

- Work in shafts or tunnels

- Use of explosives

- Work on roads with traffic management required

- Tilt-up and precast concrete erection

High-risk construction work must not commence until a SWMS has been prepared, reviewed with workers, and implemented.

Construction Projects

Definition: Construction work where total cost ≥ $250,000.

Additional Requirements:

- Principal contractor must be appointed

- WHS Management Plan required

- Site-specific induction for all workers

- Coordination of multiple contractors

Who Has Duties?

Persons Conducting a Business or Undertaking (PCBUs)

All Construction PCBUs:

- Manage risks through risk management process

- Consult, cooperate, coordinate with other duty holders

- Provide information, training, supervision

- Ensure workers have general construction induction (White Card)

If Carrying Out HRCW:

- Prepare SWMS before work starts

- Ensure workers follow SWMS

- Review SWMS if circumstances change

Principal Contractor (Construction Projects ≥$250,000):

- Prepare WHS Management Plan

- Ensure plan implemented

- Manage SWMS from other contractors

- Provide site-specific induction

- Coordinate WHS across site

- Manage general workplace arrangements

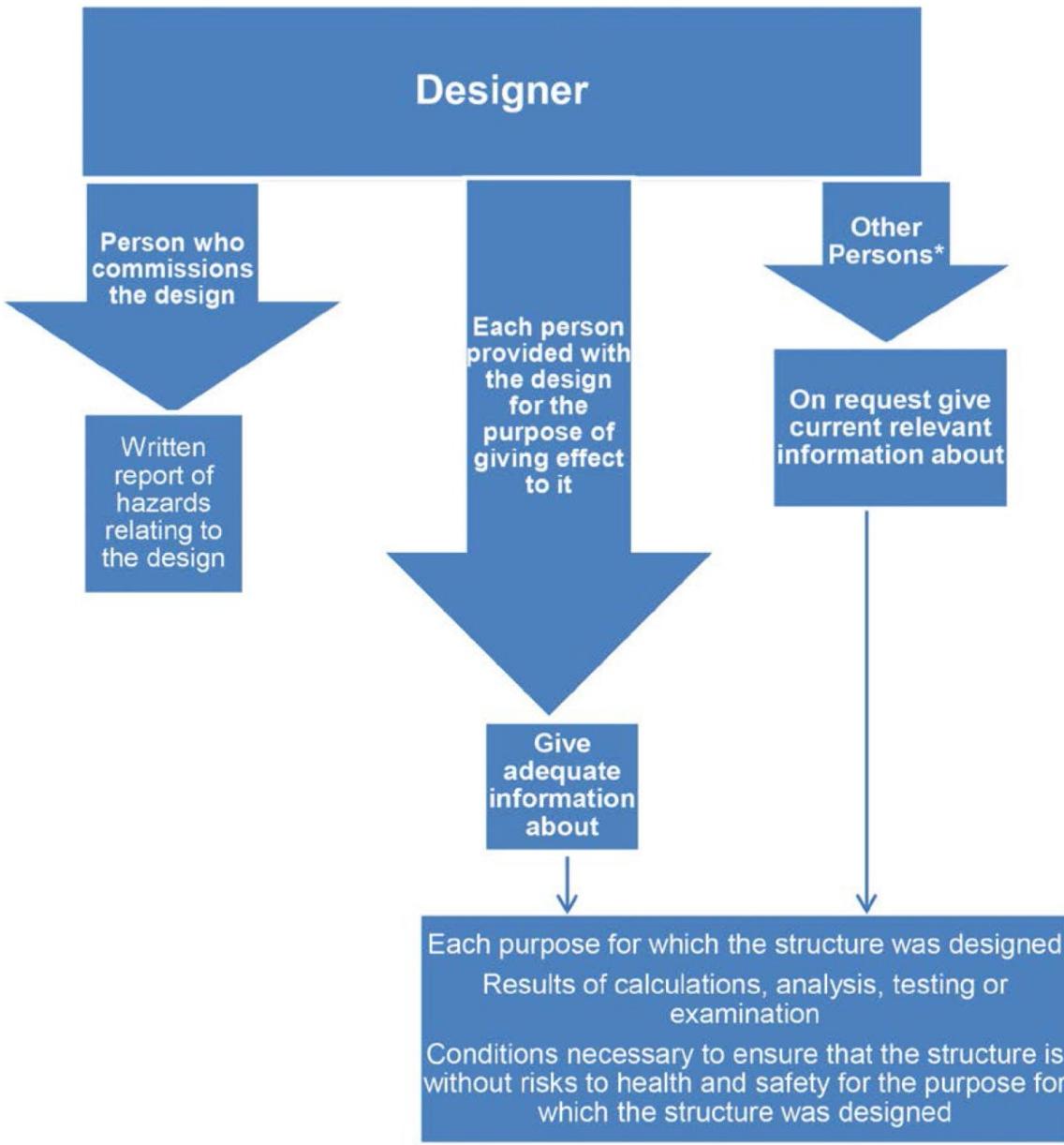

Designers

Must ensure structures, plant designed without WHS risks so far as reasonably practicable. Provide information about:

- Purpose and design

- Conditions/restrictions on use

- Safe construction, use, maintenance, demolition

See Safe Design of Structures for detailed guidance.

Workers

Must:

- Hold general construction induction card (White Card)

- Follow SWMS

- Use PPE as instructed

- Report hazards and incidents

- Take reasonable care for own and others' safety

Officers

Exercise due diligence to ensure PCBU complies with WHS duties.

See Officer Duties for detailed requirements.

General Construction Induction Training (White Card)

Who Needs It: Every worker on construction sites must hold valid general construction induction card.

Content Covers:

- WHS rights and responsibilities

- Hazards common to construction

- Risk control measures

- Emergency procedures

- Importance of consultation

Validity:

- Card valid across Australia

- Issued after completing approved training course

- Must be carried on site

- No expiry date (current cards)

Principal contractors should verify all workers have valid White Cards during site induction.

Site-Specific Induction

Required for:

- Construction projects (≥$250,000)

- All workers entering site (including visitors)

Must Cover:

- Site layout and emergency exits

- Site-specific hazards and controls

- Location of facilities (toilets, first aid, drinking water)

- Emergency procedures

- Key personnel and reporting structure

- Site rules (PPE, permits, access restrictions)

Record Keeping: Maintain record of all workers inducted (name, date, signature).

Safe Work Method Statements (SWMS)

See Safe Work Method Statements for comprehensive guidance.

Must Include:

- Description of high-risk work

- Identified hazards

- Risk assessment

- Control measures (following hierarchy of control)

- How controls implemented

- Monitoring and review procedures

Key Requirements:

- Prepared before HRCW commences

- Reviewed with workers before starting

- Readily accessible during work

- Reviewed if circumstances change

- Kept until work is completed, or for 2 years if a notifiable incident occurs

WHS Management Plans

See WHS Management Plans for comprehensive guidance.

Required for: Construction projects ≥$250,000

Must Include:

- Health and safety arrangements for project

- Consultation, cooperation, coordination mechanisms

- Site-specific induction process

- Incident and emergency management procedures

- Monitoring and review processes

Common Construction Hazards

Falls from Height

Most common cause of construction fatalities.

Sources:

- Roofs, edges, penetrations

- Scaffolding

- Ladders

- Excavations

Controls: See Managing Risk of Falls for detailed guidance.

Mobile Plant and Vehicles

Hazards:

- Collision with workers or other plant

- Rollover

- Being struck by moving plant

- Reversing incidents

Controls:

- Separate pedestrians and vehicles (dedicated walkways)

- Traffic management plan

- Exclusion zones around operating plant

- Spotters for reversing

- Proximity detection systems

- Trained/licensed operators

See Plant for detailed guidance.

Electrical

Hazards:

- Electric shock from damaged equipment, overhead/underground powerlines

- Arc flash

Controls:

- RCDs on all portable equipment

- Test and tag portable tools

- Locate underground services (Dial Before You Dig)

- Maintain safe distances from overhead powerlines

- Licensed electricians for electrical work

See Electrical Risks for detailed guidance.

Excavation

Hazards:

- Collapse of excavation walls

- Falls into excavations

- Underground services (gas, electricity, water)

- Vehicles reversing near excavations

Controls: See Excavation Work for detailed guidance.

Confined Spaces

Hazards:

- Oxygen deficiency

- Toxic/flammable atmospheres

- Entrapment

Controls: See Confined Spaces for detailed guidance.

Noise

Common Loud Equipment:

- Concrete saws, grinders, jackhammers

- Generators, compressors

- Heavy plant

Controls: See Noise for detailed guidance.

Hazardous Substances

Common Construction Substances:

- Silica dust (concrete, masonry cutting)

- Asbestos (in existing structures)

- Paints, solvents, adhesives

- Welding fumes

Controls:

- Water suppression for dust

- Proper ventilation

- Respiratory protection

- Health monitoring where required

See Silica Dust, Asbestos, Hazardous Chemicals.

Manual Handling

Common Tasks:

- Lifting materials (cement bags, bricks, timber)

- Repetitive tasks (bricklaying, nailing)

- Awkward postures

Controls: See Manual Handling for detailed guidance.

Workplace Management Arrangements

Access and Egress

- Safe pedestrian access (separated from vehicles)

- Stairs/ramps/ladders to different levels

- Clear, well-lit pathways

- Protected from falling objects

Housekeeping

- Clear walkways daily

- Remove rubbish regularly

- Store materials safely

- Clean up spills immediately

Falling Objects

- Barricades and exclusion zones below overhead work

- Mesh/screens on scaffolding

- Tool lanyards for working at height

- Hard hat areas clearly marked

Facilities

See Work Environment and Facilities:

- Toilets and washing (1 per 15 workers minimum)

- Drinking water (ample, cool, clean)

- Eating area (shelter, seating, away from contaminants)

- First aid facilities

- Protection from weather

Personal Protective Equipment (PPE)

Minimum Construction PPE:

- Hard hat (AS/NZS 1801)

- Safety boots with toe protection (AS/NZS 2210)

- High-visibility clothing (day/night use as required)

- Eye protection (for grinding, cutting, chipping)

- Hearing protection (where noise >85dB)

- Gloves (task-appropriate)

Task-Specific PPE:

- Respirators (silica dust, welding fumes)

- Fall arrest harnesses (working at heights)

- Face shields (grinding, chemical splash)

PPE does not eliminate hazards. Always implement higher-level controls first.

Emergency Planning

Construction sites must have:

- Emergency evacuation procedures

- Assembly points

- Fire extinguishers (appropriate types)

- First aid kits and trained first aiders

- Emergency contact numbers (displayed prominently)

- Procedures for notifying emergency services

Emergency Drills: Conduct evacuation drills regularly (minimum quarterly for long projects).

See Emergency Planning for detailed guidance.

Consultation, Cooperation, Coordination

Consultation

Must consult with workers on:

- Identifying hazards and assessing risks

- SWMS development and review

- Changes affecting WHS

- Facilities and amenities

Methods:

- Toolbox talks

- Health and Safety Representatives

- Safety committees

- SWMS reviews

See Consultation Requirements.

Cooperation and Coordination

Multiple PCBUs on site must:

- Share WHS information

- Coordinate activities to avoid creating risks

- Inform each other of hazards and controls

- Coordinate emergency response

Principal Contractor Role: Facilitates cooperation and coordination through WHS Management Plan.

See Cooperation and Coordination.

Incident Reporting and Investigation

Notifiable Incidents: Must notify SafeWork NSW immediately (13 10 50) if:

- Death

- Serious injury/illness (hospitalization, amputation, etc.)

- Dangerous incident (collapse, explosion, etc.)

Preserve Site: Do not disturb incident scene (except to help injured, make safe, or with regulator permission).

Investigate:

- Identify immediate and underlying causes

- Implement corrective actions

- Review controls

- Document findings

Practical Construction Example

Scenario: Two-storey residential construction

Project Details

- Total cost: $450,000 (construction project)

- Duration: 6 months

- Peak workforce: 25 workers

- Multiple contractors (builder, plumber, electrician, etc.)

WHS Management Structure

Principal Contractor: Builder appointed, responsible for:

- WHS Management Plan prepared

- Site-specific induction program

- Coordination of all contractors

- Management of workplace arrangements

SWMS Required For:

- Excavation (>1.5m deep)

- Formwork and concrete pouring at height

- Roof framing and sheeting (fall risk >2m)

- Scaffolding erection

- Electrical work near overhead powerlines

Site Setup

Access:

- Pedestrian gate separate from vehicle entry

- Marked walkways

- Temporary stairs to upper floor (handrails both sides)

Facilities:

- 2 portable toilets

- Drinking water cooler (iced in summer)

- Lunch shed with tables

- Hand washing station

- First aid kit in site office

Signage:

- Site entry sign (project details, emergency numbers)

- Hard hat/hi-vis/safety boots mandatory

- Exclusion zones (excavation, crane operations)

- Emergency assembly point

Daily Site Management

Morning:

- Pre-start toolbox talk (hazards for the day, SWMS review)

- White Card checks for new workers

- Site-specific induction for first-time visitors

- Pre-start plant inspections

During Day:

- Supervisor monitors compliance with SWMS

- Regular site inspections

- Coordination meetings if multiple high-risk activities

End of Day:

- Site cleanup

- Secure site (fencing, lighting)

- Lock away tools and materials

Results

- Zero lost-time injuries over 6-month project

- Regular toolbox talks maintained awareness

- Effective coordination prevented conflicts between trades

- All SWMS followed, reviewed when conditions changed