Excavation Work

What is Excavation Work?

Excavation means removing soil or rock using tools, machinery or explosives to form open trenches, holes or cavities.

Common Construction Excavations:

- Trenches for footings, services, drainage

- Bulk excavation for basements, cut-and-fill

- Service pits

- Bored piles

When is Excavation High-Risk Construction Work?

Excavation is HRCW requiring SWMS if:

- Depth > 1.5 meters, OR

- Risk of person falling in (any depth)

Major Hazards

Collapse of Excavation Walls: Most serious risk - can bury and kill workers instantly.

Underground Services: Striking gas, electricity, water, telecommunications.

Falls into Excavation: Workers or public falling in.

Mobile Plant: Excavators, trucks reversing near excavation edge.

Asphyxiation/Toxic Atmosphere: Deep excavations may have oxygen deficiency or toxic gases.

Before Excavating - Service Location

Striking underground services causes deaths, serious injuries, major disruptions. Service location is mandatory.

Process:

1. Dial Before You Dig (1100):

- Call at least 2 business days before excavating

- Obtain plans showing underground services

- Free service

2. Locate Services on Ground:

- Use plans and cable/pipe locators

- Mark position with paint or pegs

- Assume all services are live and pressurized

3. Hand Dig to Expose:

- Within 500mm of marked services, hand dig only

- Use spades/shovels (not picks or mattocks)

- Carefully expose services

- Confirm type, depth, condition

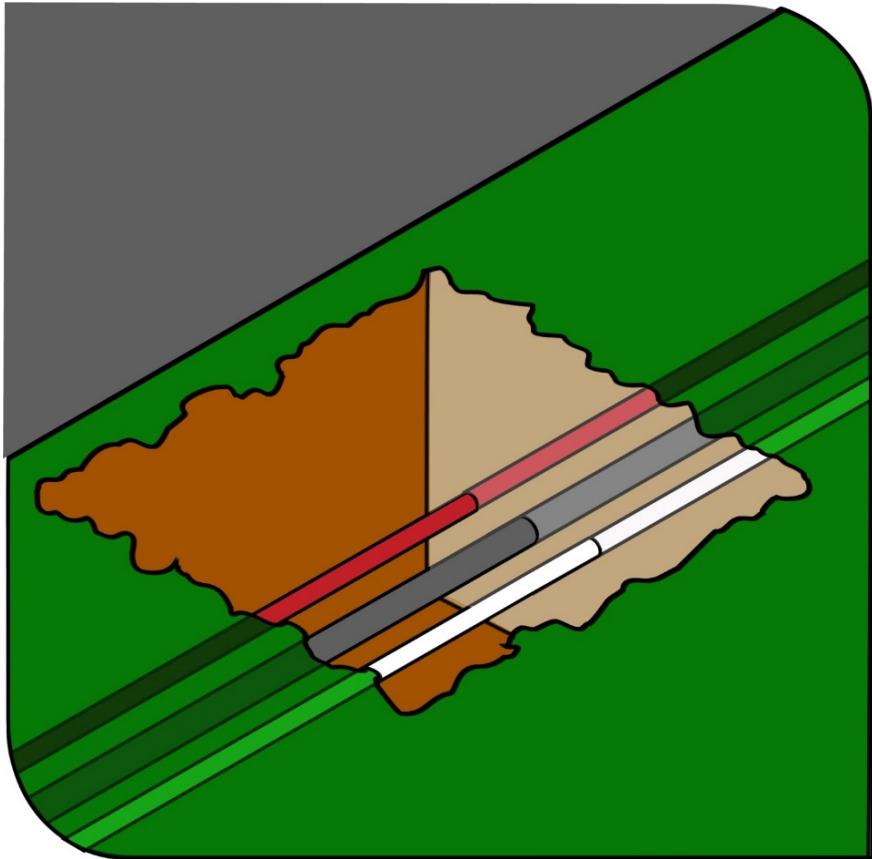

Figure: Underground essential services exposed by potholing

Figure: Underground essential services exposed by potholing

4. Protect Exposed Services:

- Support services crossing excavation

- Protect from damage

- Maintain clearances

- Backfill properly when complete

Preventing Excavation Collapse

Assessing Collapse Risk

Factors Affecting Stability:

- Soil type (clay more stable than sand)

- Moisture content (wet soil less stable)

- Depth

- Nearby loads (plant, stockpiles, traffic)

- Vibration

- Previous excavation/disturbance

When is Shoring/Battering Required?

- Always for excavations >1.5m in unstable soil

- Any excavation where collapse risk exists

- Competent person assesses stability

Control Measures

Level 1: Elimination

- Avoid excavation (alternative construction methods)

- Trenchless technology (pipe bursting, boring)

Level 2: Engineering Controls

Battering (Sloping Walls):

- Cut walls at safe angle (typically 1:1 or flatter)

- Depends on soil type

- Requires more space

- Most reliable for short-duration work

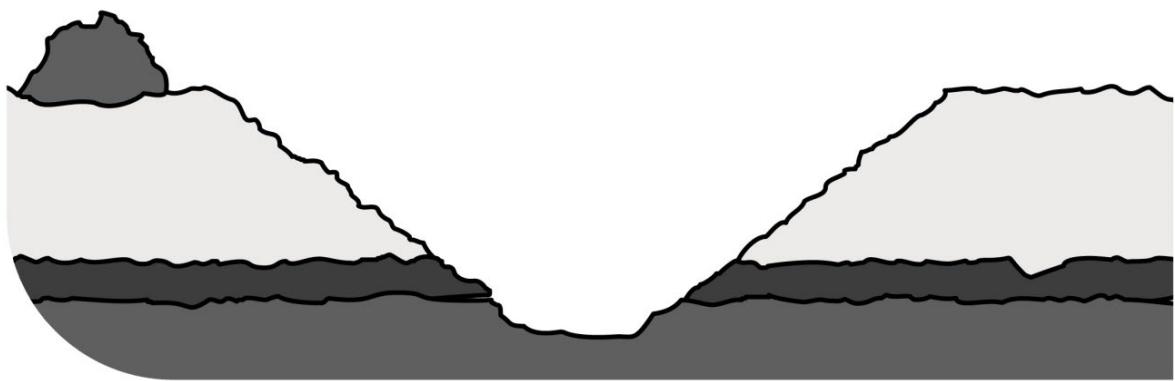

Figure: Battering - sloping walls

Figure: Battering - sloping walls

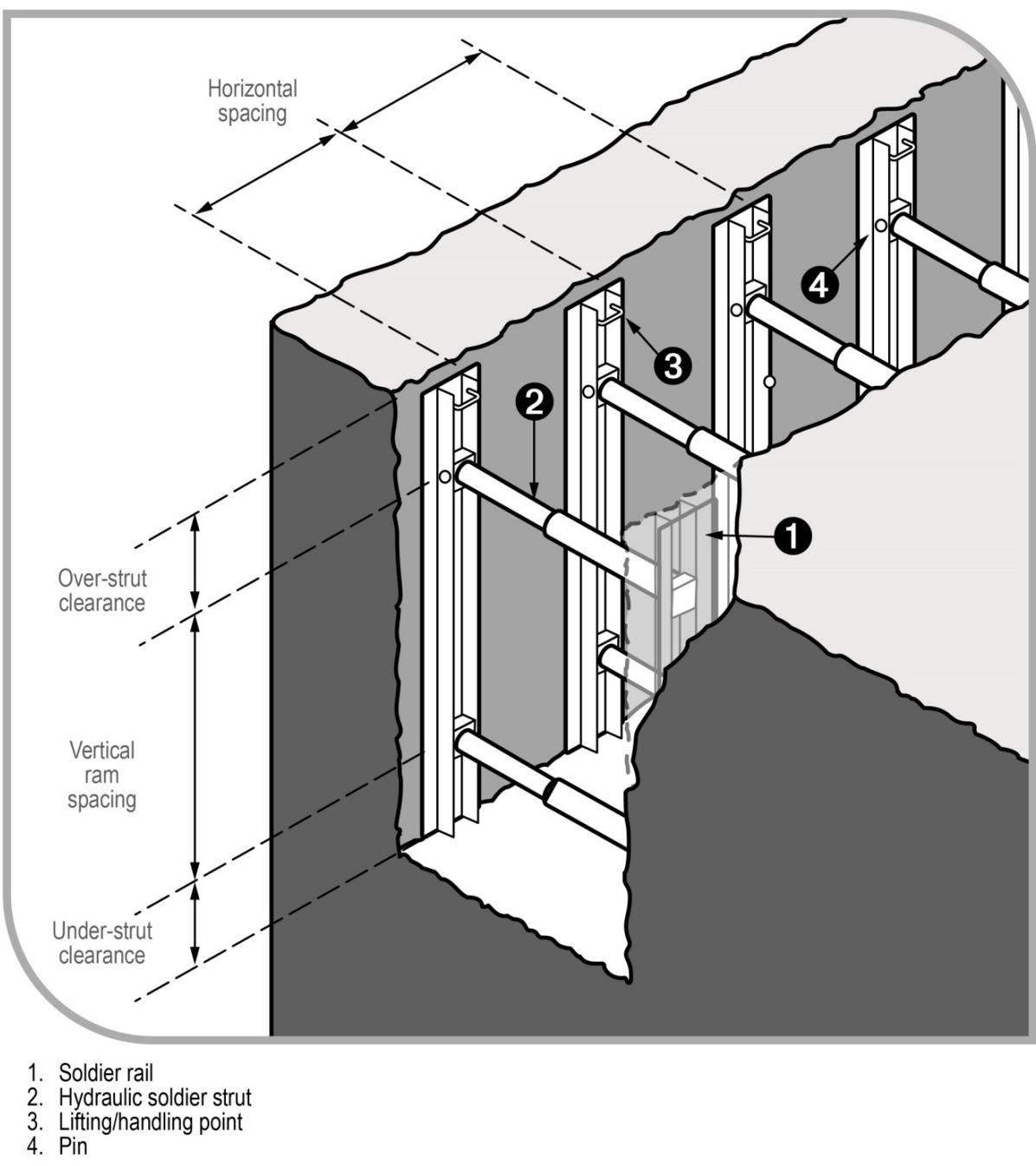

Shoring (Prevents Collapse):

- Hydraulic/mechanical supports hold walls

- Prevents collapse from occurring

- Allows vertical walls (less space)

- Must be designed by competent person

- Installed progressively as excavation deepens

- Removed carefully during backfilling

Figure: Hydraulic shoring (soldier set style)

Figure: Hydraulic shoring (soldier set style)

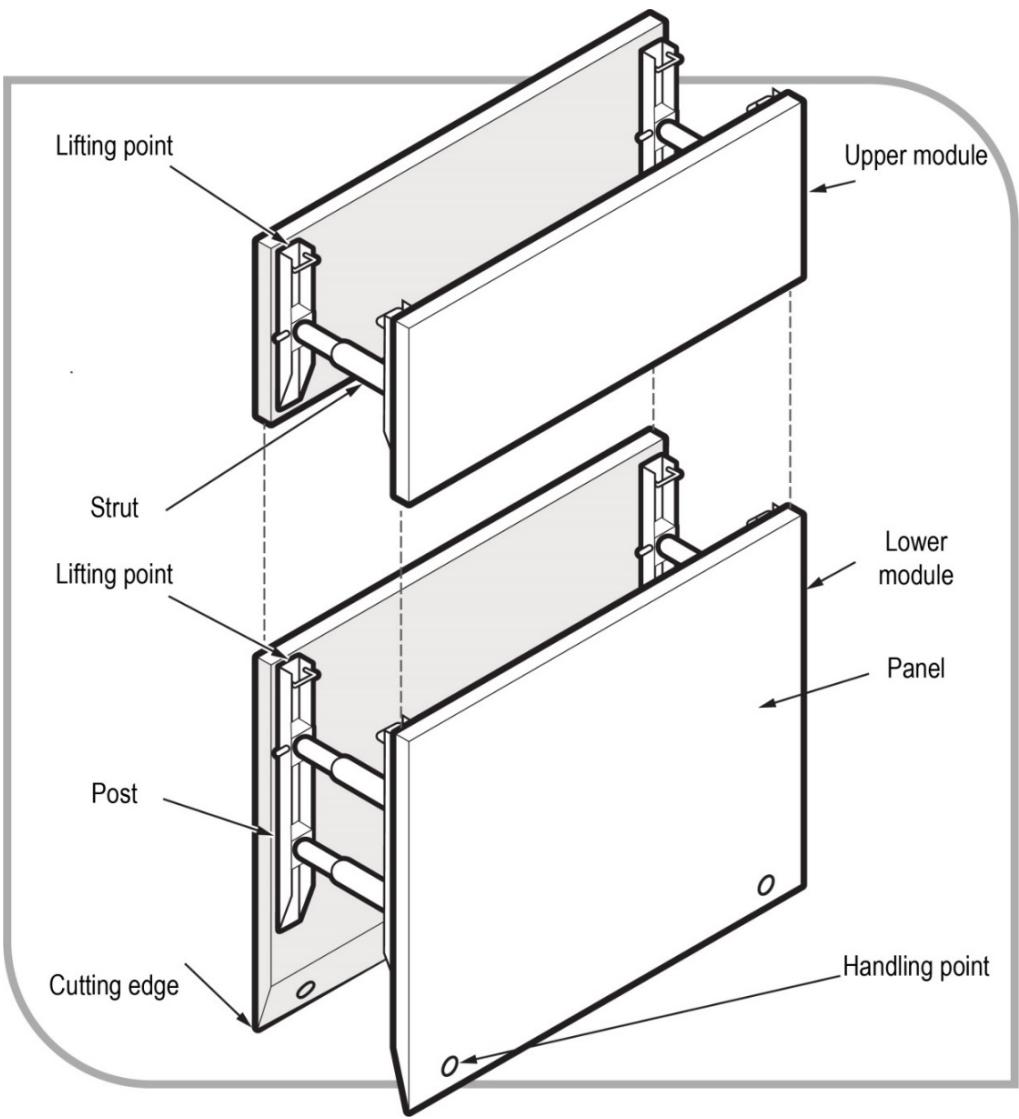

Shields and Boxes (Protects Workers):

- Designed to protect workers if a collapse occurs

- Does not prevent collapse of excavation walls

- Only for worker safety, not ground support

- Do not assume shield will hold up a wall

Figure: Typical trench shield

Figure: Typical trench shield

Benching:

- Step excavation in stable soil

- Reduces wall height

- May combine with battering

Figure: Benching

Figure: Benching

Level 3: Administrative/PPE

- Exclusion zones

- Barricades/barriers

- Warning signs

- Competent supervision

- SWMS

- PPE (hard hats, boots, hi-vis)

Inspection

Daily Inspection Required:

- Check for cracks, subsidence

- Check supports tight and secure

- After rain, vibration, ground movement

- By competent person

Safe Access and Egress

Requirements:

- Safe means of entry and exit

- Ladder secured, extends 1m above excavation

- Clear path to access point

Deep Excavations: Multiple access points may be needed.

Edge Protection

Falls into Excavation:

- Barriers approximately 1.5m from edge (prevents collapse and falls)

- Guardrails if excavation remains open

- Covers over narrow trenches (must support traffic loads)

- Adequate lighting

- Warning signs

Exclusion Zones: Keep plant and vehicles back from edge (minimum 1.5 times excavation depth).

Stockpiles and Spoil

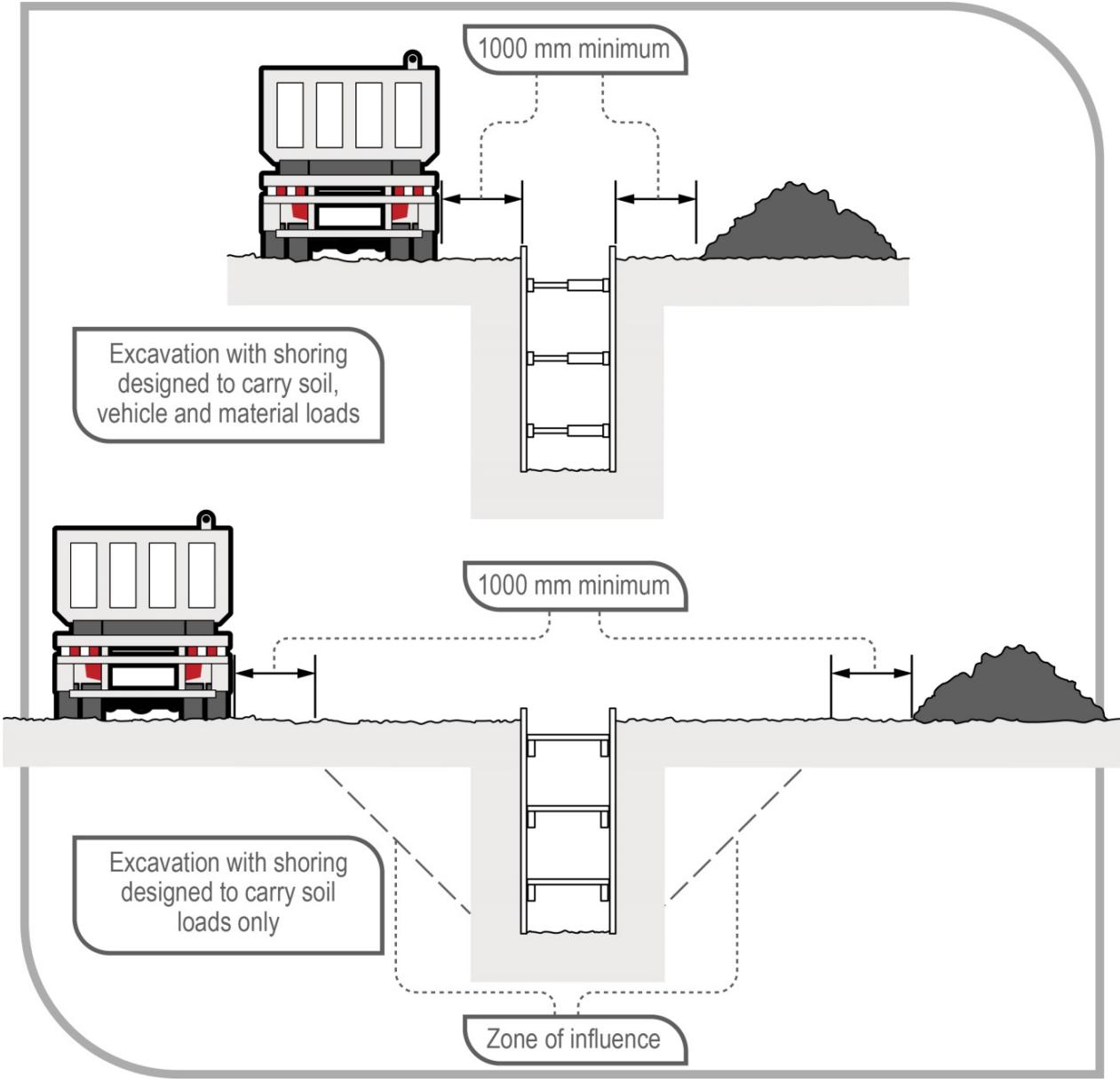

- Minimum at least 1m (1000mm) from excavation edge (prevents surcharge loading)

- Consider wall stability when placing

- Do not undercut stockpiles

Figure: Excavated material and loads near excavations - Effect of zone of influence

Figure: Excavated material and loads near excavations - Effect of zone of influence

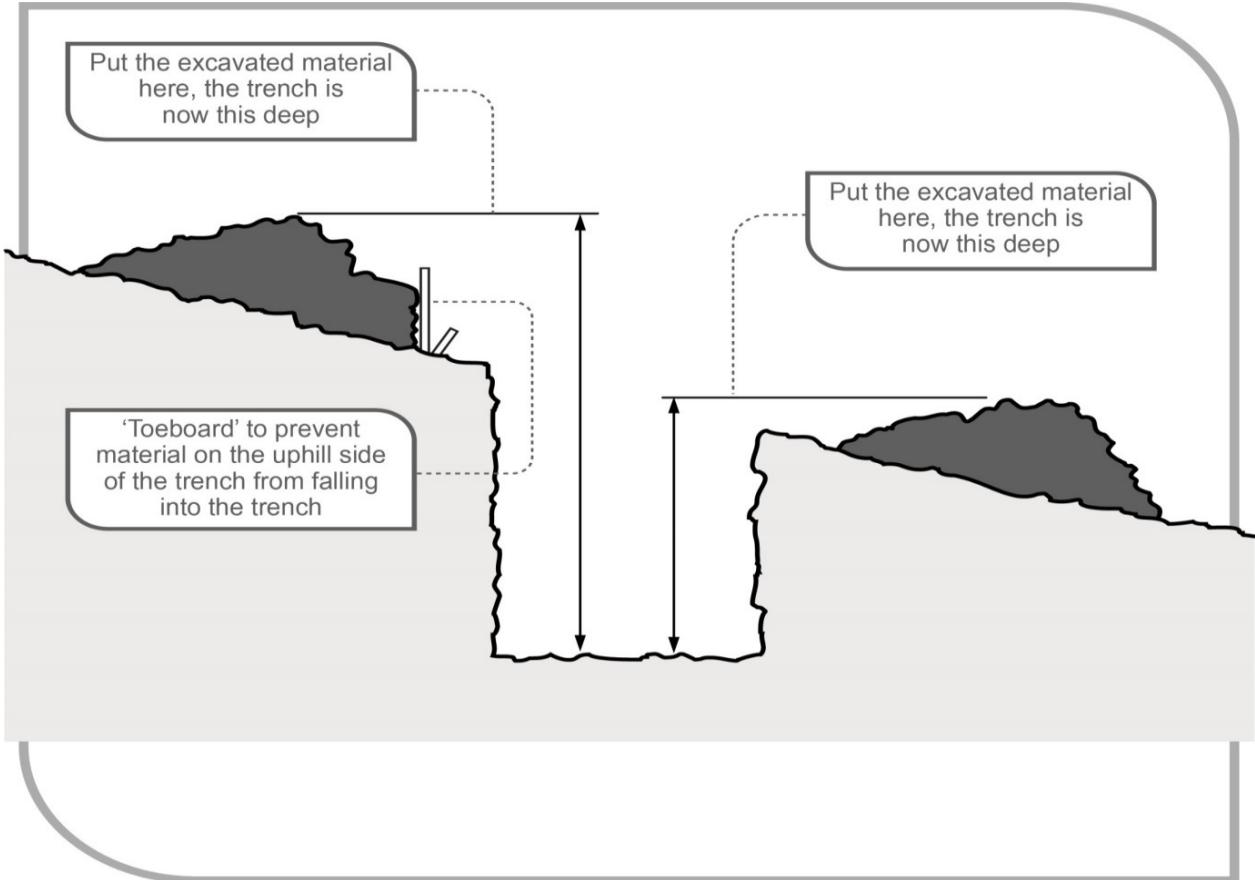

Figure: Placing material on lower side reduces effective depth

Figure: Placing material on lower side reduces effective depth

Confined Space Considerations

Deep Excavations May Be Confined Spaces:

- Limited entry/exit

- Unfavorable atmosphere

- Not designed for continuous occupancy

When Confined Space: Apply confined space requirements:

- Atmospheric testing

- Ventilation

- Entry permits

- Rescue procedures

Dewatering

Water in Excavation:

- Destabilizes walls

- Slip/drowning hazard

Controls:

- Pump out water

- Cut off water source

- May require engineered dewatering system

- Monitor wall stability (water removal can cause collapse)

Practical Example

Scenario: Excavating trench for sewer line (2m deep, 50m long)

Before Excavating:

- Dial Before You Dig - plans obtained

- Services marked (water main, electricity, telecommunications)

- Cable locator confirms positions

- Hand dig trial holes - services exposed and confirmed

- SWMS prepared

During Excavation:

- Excavator maintains 500mm clearance from services

- Hand dig close to services

- Walls battered 1:1 (stable clay soil)

- Ladder every 15m

- Barriers 1.5m from edges

- Daily inspections before work

Result: Excavation completed safely, no service strikes, no collapses.